To pass on the knowledge and expertise built up during the Interreg project BHC21 to companies so that it can be exploited, Sirris has built a demonstrator cell that shows the benefits of digital operator support. This was presented during the Open Lab Day on 8 March. A look back.

BHC21 project

Today, assembly companies deliver more and more custom work and the jobs are much more complex than they used to be. As a result, many companies find it difficult to attract qualified personnel. At the same time, many low-skilled people fail to get into the labour market. These are the issues that the Interreg project Boosting Human Capital in the 21st Century (BHC21) sought to address. After more than three years, the project - which aimed to develop more efficient and effective vocational training for the low-skilled - was completed in October 2022.

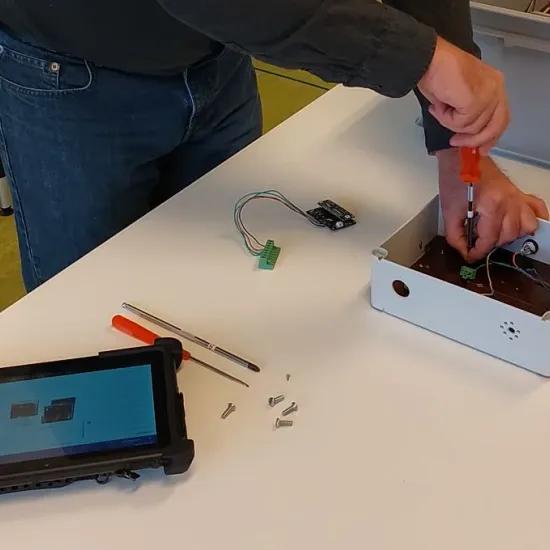

Sirris has built a demonstrator to show practical applications of the knowledge and expertise acquired during the project so that it can be passed on to the companies. The benefits of operator support can be shown and tested in the cell. The interactive workstation is fitted-out with many innovative technologies and forms an extension of the existing assembly line at our site in Kortrijk. The cell serves as a demonstrator that will make the new technologies for preparing low-skilled people for a job in industry better known to companies and organisations.

Interested parties were able to get acquainted with the demonstrator and its potential during the operator support Open Lab Day on 8 March.

Open Lab Day dedicated to training and technology

The Open Lab Day was opened by Bart Verlinden, theme manager for Industry 4.0 at Sirris. The first speaker was Diana Faifer, who is active at POM West Flanders and project leader of BHC21. She gave an overview of the project and its results, relevant for anyone interested in innovative learning methods for low-skilled people. Carlo De Smedt, didactic expert of the VDAB, shared some concerns with the attendees and described the challenges involved in introducing learning technologies. This was an important topic, as the development of new technologies requires new skills and training.

A Sirris expert then introduced the new work cell under development in Smart & Digital Factory and outlined its potential. He showed how the operator is assisted by digital work instructions in combination with an automatic picking detection system. This system detected when the operator took something from a container and automatically moved to the next instruction. The system thus increases the certainty that the operator took the right part and then makes it easier for him by not having to click himself to go to the next instruction. To minimise errors in processing new orders, we are working with a CPQ system in this demo. This allows customers to enter orders themselves via an online customer portal. In this way, only items that can actually be produced can be compiled and ordered.

This open lab day was an excellent opportunity to learn more about the results of the BHC21 project and to get acquainted with operator support technologies.

Were you unable to attend? We made a video of the event that gives a good impression of the various presentations.

Would you like more information about a specific part? Then be sure to contact the expert in the field!