Digitisation brings important opportunities, but it is not always easy to do. With the help of Sirris and the Voka Digihub, Diamond cutting company Almax-easylab developed a digital system to make it easier to track the quality of diamonds.

Diksmuide-based diamond cutting plant Almax easyLab combines craft and technology in diamond processing for universities and research centres, specifically for research on high pressure research, which involves diamonds intended for fundamental scientific research, for example on superconductors. Only 5 or 6 similar specialists exist worldwide. This family business employs about 20 people, including 12 gemcutters, who are trained internally. It takes 2-3 years to become a fully trained gemcutter.

Building on existing processes

Managing director Koen De Hantsetters had been looking for some time for a better, more convenient way to save and process diamond quality data during the cutting process. However, in a small SME all too often there is insufficient time and in-house knowledge to develop such a system. He heard about Sirris through Voka West Flanders' Digihub project: "I had my own concrete idea, but did not see a solution. The people at Sirris were keen to explore our challenge."

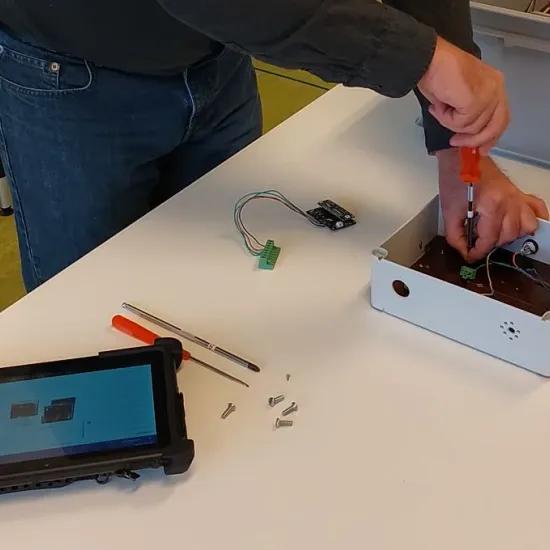

The Sirris expert came to the site to study the production process. The software environment and measurement methods and devices within the company were all taken into account. Almax easyLab was already collecting data on the changing quality of diamonds during the production process, but this was done on paper. This often required them to browse through papers to see if, where and how something had gone wrong. When this process is digitised and centralised, people can be notified automatically if something goes wrong.

Low-threshold digitisation

One of the conditions Koen De Hantsetters found essential was that the new system should be low-threshold for gemcutters and should not be too much extra work. Sirris devised a solution consisting of three elements: for each stone a QR code is created, plus a configurator with the diamond's properties. That QR code should be linked to print screens with the diamond's quality data during the cutting process. All that data is then collected in a database and accessed and filtered through Microsoft Power BI so that the right conclusions can be drawn.

The project took only four months, but the solution proved to be very convenient: the gemcutter only has to enter the property of a potential problem, almost without any additional work, into the system. The company now feels confident enough to tackle other issues as well.

Read the full story of Almax easyLab here.

You can read more about the Voka DigiHubs in the following article.

Are you also interested in realising such an automation or would you like to know more about it? Please contact us for details!

Or get further inspiration from other case studies, such as this one from Labrints.