Possibilities with digital work instructions keep expanding

Digital work instruction systems are still going strong. A logical evolution, given that they seem to respond seamlessly to contemporary trends and needs. By integrating digital tools and AI, operators can quickly gain access to correct and relevant knowledge. So what can you, as a manufacturing company, expect from such systems? What are the advantages and opportunities over existing alternatives?

The need to efficiently support operators in their increasingly extensive and rapidly changing range of tasks is growing. This is where digital tools can provide a solution.

Evolution in production requires different approach

In recent years, manufacturing industry has clearly evolved from mass production to the production of smaller series of customer-specific products. In addition, customers want their products to be delivered as soon as possible and at the keenest possible price. This shift has led to lower volumes and has made production more complex. This can be seen in all aspects of manufacturing, from planning and control to production logistics and the production processes themselves.

Exactly how this transition can be made is not always obvious to production operators. Whereas in the past people had to make more-or-less the same item for years, they now have to keep switching between products. Managing this complexity is a major challenge.

Moreover, technically proficient employees are difficult to find, and with high job turnover, experienced operators will leave or retire without passing on all they know. In mass production, it is usually enough for an operator to have had relevant on-the-job training and to have carefully read the production manual - which might be a technical dossier, CAD file or assembly instructions - for things to keep running. For the production of smaller series of customer-specific products, however, extra attention is paid to ensuring that the product is built according to the specific requirements of the customer. Each product then requires specific instructions. Instruction methods such as working through a traditional production manual, work instructions created in Word or a PowerPoint presentation soon reach their limits.

In recent years, many new technologies have been introduced to support operators: whereas cobots, industrial robots and mobile robots are mainly used to take over certain (physical) tasks from the operator, there is also an increasing number of digital tools that can take up some of the operator’s cognitive burden. The design principle behind these technologies and applications is simple - the right information, at the right time and in the right place.

Advantages of digital operator support

It is not surprising, therefore, that digital operator support is increasingly finding its way onto the factory floor. Digital support has a number of clear benefits for your operators:

Access to the most relevant information

- Up-to-date information: The operator always has access to the latest information. Instructions can be amended at the last minute without disrupting production.

- Personalised information: By scanning, for example, both the order and the operator, personalised instructions can be provided that take the operator’s skill level into account. This saves the operators from having to look up the correct work instructions themselves.

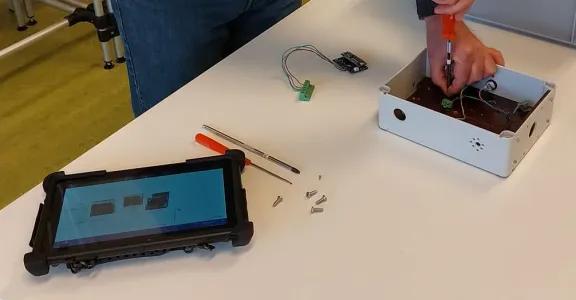

- Diversified information: Information can be provided in different forms, including photos, animations and videos.

- Interactive information: Interaction can be enabled, allowing for feedback, working through checklists, etc.

- Linked information: instructions can be loaded on the basis of a job number or scan code (or a direct link to the ERP/MES system can be made) so you can log critical information, such as whether or not to perform an important quality control or record production times.

- Mobile information: the information can be provided via various carriers, such as a smartglass, tablet, screen or a AR/VR headset, which lets you work when mobile and even remotely.

New and wide-ranging possibilities

In many cases, digital instruction systems not only have added value over traditional (paper) instructions, they can also open up many new possibilities:

- Many digital work instruction systems allow you to enter measured values and to tick the checklists as having been completed and checked. In this way, quality can be guaranteed and audits can be carried out easily.

- Reporting function: Some systems (or modules) allow the operator to report errors, formulate comments to improve the work and even propose design changes.

- Measuring production times: when you navigate through different screens in order to carry out a job, you can also keep track of the times and thus gain a better understanding of the time taken for each production step.

- Process control/quality assurance: By scanning the job and operator, it is possible to track which operations were carried out by whom and on which product (this may be related to a serial number, for example). Defects can then be traced, which can lead to better guidance for the operator (further training) or design changes.

- Nowadays, AI tools are available to help you create work instructions.

Impact on production, process and operator

Digital instruction systems have an effect on quality and production time. The effect on quality is greater than the effect on production time. In some augmented reality applications, the quality problems can even disappear completely.

Digital tools give you a better insight into how efficient your work processes are. The tools can also indicate operator training needs.

Digital instruction tools accelerate the learning process during the training phase. For simple tasks, the benefit of using digital instructions during actual production is rather limited, but increases as tasks become more complex or error-prone.

Digital instruction systems not only improve the work of the operators but also simplify the creation and management of the instructions by production engineers.

The most commonly used systems are very affordable, which means that every manufacturer can consider a pilot project with digital work instructions.

Could digital work instructions be useful in your company?

Are you interested in how the integration of digital work instructions can make your production operators (even) better? On 25 January 2024, Sirris will organise a hands-on masterclass on this current topic. We will show you the way with digital work instructions and their integration in your factory. We will also show you a wide range of solutions and tools so that you can make the right choice for your company and its activities. You can also experiment yourself, with explanation provided by our experts. Practical information and the option to register can be found in our agenda.