Connected Manufacturing | On the road to transparent production

The Connected Manufacturing project aims to give companies a better idea about the technological possibilities to connect machines and business applications and give businesses insight into how they can be used for increased transparency and productivity.

Context

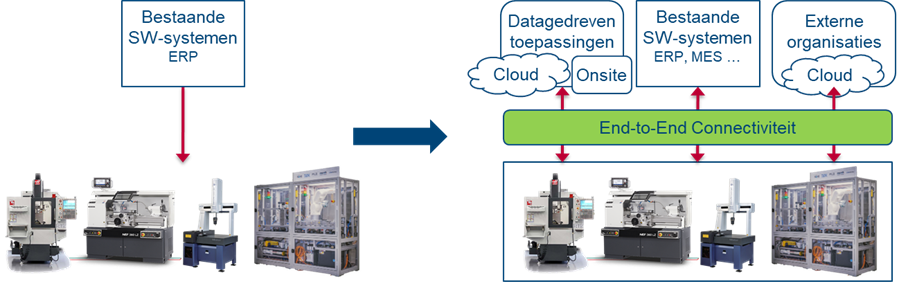

The transition from mass production to small series of complex custom-made products with high added value and short lead times has increased the complexity of production processes of Flemish manufacturing companies. As a result, the productivity is under pressure. Digital technologies make it possible to connect machines, extract data from these machines and use this data to improve production. The various software applications (ERP/MES/...) can also be integrated with each other, allowing the captured data to be brought seamlessly to the desired processing level. This can increase transparency and productivity in manufacturing companies.

However, despite the potential of these digital technologies, the number of industrial applications remains too limited for the time being.

Objective

Connected Manufacturing wants to accelerate the introduction of these technologies to Flemish SMEs in the manufacturing industry. Generally applicable connectivity solutions for existing production systems and new generations of machines will be developed for this purpose. These allow a heterogeneous machine park to connect to existing software systems or new applications, locally or in the cloud.

Approach

Through representative use cases of SMEs from the manufacturing industry and machine builders, this collective research project deals with the following subaspects:

- Generating different dashboards for various applications, which provide (near) real-time insight into what is happening in production.

- A feedback of data from the production floor to the existing ERP system, so that the planning can be adjusted to the current state of production.

- The exchange of data between manufacturing company and machine builder/integrator for the start-up of digital services by machine builders or integrators for customers.

- The optimal use of production data for a more targeted control of operators.

The project provides an overview and insights into the possible technologies and standards to connect heterogeneous machinery, extract data from it and link it to higher-level systems (end-to-end connectivity).

Two demonstrators focus on the different practical aspects and give the SMEs an insight into the possible applications of the developed concepts and building blocks.

Workshops and a training programme support accelerated knowledge building among SMEs and give them the opportunity to experiment with the concepts, building blocks and technologies themselves.

Target group

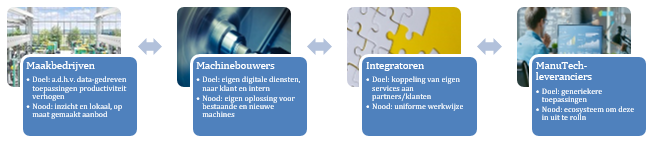

The project focuses on cooperation between all actors in the value chain (machine builders, integrators and ManuTech suppliers). All these actors are represented and the project support group therefore includes all stakeholders. They provide input for the specification of typical applications and provide representative use cases. The members of the user group will have priority when it comes to knowledge acquisition and are invited to experiment with relevant cases.

Reference

VLAIO COOCK Connected Manufacturing, HBC.2020.2544

Plus d'info à propos de notre expertise

Online advice

You have questions concerning production connectivity? Or you want advice on how to start connecting your production? Don't hesitate and ask for a free online advice with one of our experts. Click this button to reserve your time slot.