At the start of the coronavirus crisis, the University of Liège (ULiège) developed a test providing for the large-scale automation of the detection of SARS-CoV-2, the virus responsible for COVID-19. This technical development ensured that 5000 PCR tests could be produced from the outset and has since increased further.

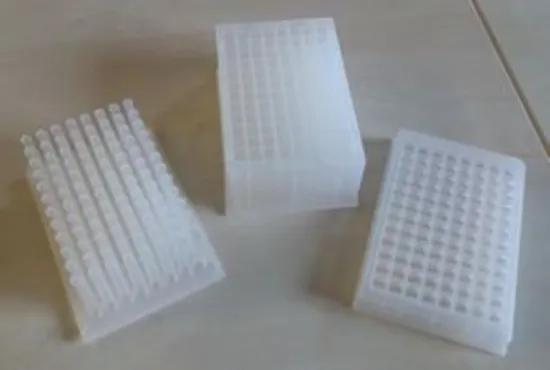

After fine-tuning the automation method and supply security of the reagents, the University of Liège joined forces with the MécaTech Cluster, Sirris and two other Walloon companies to develop an original method to produce 96-hole containers in Wallonia. These containers were no longer available during the coronavirus crisis, but were urgently required for the analysis of test samples. The autonomous production of this item assured test capacity in Belgium and was also a key factor in the development of the University of Liège analytical method to significantly increase the number of daily tests.

The polymer containers were required to scale up testing, but these were no longer available on the market due to increased demand. Research was conducted into an alternative solution for restocking with containers of sufficient quality, to meet the demand caused by the shortage.

The University of Liège immediately contacted the MécaTech Cluster, an association of 250 industrial and academic entities involved in joint innovative projects in Wallonia. Their cluster and financial partner Sowalfin decided to turn to the Sirris in Liège.

From scanning to industrialisation

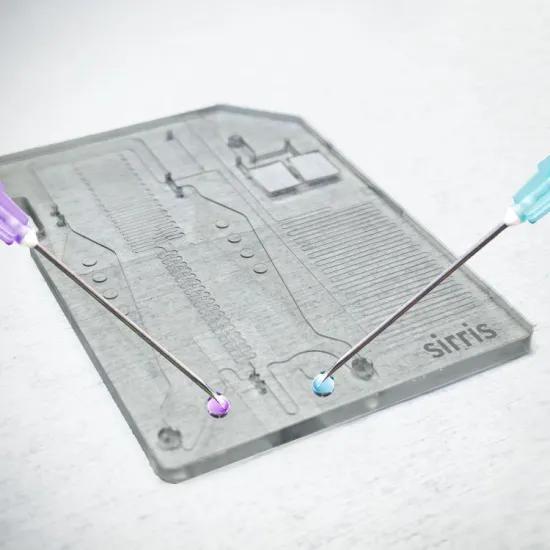

Sirris deployed their expertise and industrial network to provide specific technological solutions. The project soon started up and the follow-up was discussed with the industrial partners involved, resulting in the items going into mass production. The University of Liège validated the items as soon as five weeks later.

As Sirris did not have a technical description of the items to be produced, the experts scanned the existing containers and used the results to create 3D models of the components.

The project follow-up consisted of bolstering the industrial chain to enable it to produce injection- moulded polymer components on a large scale. U Liège required large numbers of containers. From the outset, the project aimed at manufacturing 40,000 units. 3D printing is not appropriate for such a large quantity of high-quality products in a short period, which meant searching for companies that were able to handle large-scale production. Sirris continued to provide support in the industrialisation phase and during the operational implementation of the industrial production.

Sirris called on their industrial partner network and quickly found mould construction and injection-moulding companies: HTP Europe in Dottignies and MTU in Evregnies, respectively. Sirris also validated the shapes by producing three visual and functional prototypes, and developed an injection mould.

Test capacity decreases dependency

The objective at of the University of Liège was to decrease the dependency of products that could become scarce in their region due to testing capacity, which is essential in a pandemic. It therefore became possible to produce in Wallonia the 96-hole containers required for the tests.

This project is a good example of the efficiency, agility and speed of Walloon entities during a crisis.