Superhydrophobic surfaces and mimicking nature

In recent years, considerable attention in surface engineering research has been directed towards superhydrophobic surfaces - surfaces that exhibit extremely high resistance to wetting by water. In this context, new technologies such as femtosecond laser texturing have opened up the possibility to mimic surface structures from the natural world.

The most common examples of surface structures found in nature are the lotus leaf (with low adhesion to water droplets, which cannot remain stable but spontaneously roll off the surface) and rose petal structures (with high adhesion to water droplets, which cannot move even at high tilted angles on the surface). These examples demonstrate that it is possible to tune the wettability of a material surface to achieve a specific property for a desired application.

Wettability states and control through laser texturing

There are four different wettability states defined by engineers based on the angle formed between the water droplet and the contacting solid surface:

- superhydrophilic (contact angle is less than 10°)

- hydrophilic (contact angle between 10° and 90°)

- hydrophobic (contact angle between 90° and 150°)

- superhydrophobic (contact angle over 150°).

By using femtosecond laser texturing direct application, it is possible to control the wettability of a surface: this by tailoring not only the contact angle, but also the stickiness of a water droplet in relation to the solid surface.

Laser texturing approaches and applications

Two approaches are used for laser texturing a surface to modify wettability: the formation of nanostructured topography, known as LIPSS (laser-induced periodic surface structure), and the so-called hierarchical topography (with structures such as columns or pillars in the range of microns covered by LIPSS nanostructure). These artificially constructed topographies are used in a variety of applications. Just to keep within the area of wettability applications, these properties can be employed in superdry surfaces, antifogging, self-cleaning, water-resistant and anti-icing application

Results and future steps @Sirris

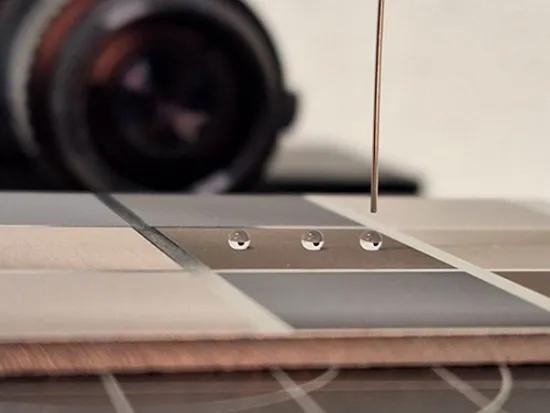

At Sirris we are currently developing ways to speed up the process of laser texturing for both flat parts and shafts. We aim to assist machine and mould makers in meeting their demand for superhydrophobic surfaces, and we are making significant progress in this direction. Recent results show that it is possible to achieve water repellent, superhydrophobic surfaces with different micro textures, as shown in the graph below comparing round pillars, squared columns and LIPSS.

As the next steps in our research, we intend to develop alternative, faster ways to apply laser texturing via indirect methods. This can be done for both metallic or polymeric parts. In the former case, an investigation into the rolling process of flat parts will be performed as an attempt to imprint the texture in a precise, repeatable operation. In the latter, the texturing of moulds will be put to the test. Another important task will be assessing the wear and resistance of such textures to finally validate their functionality in real-world mass applications.

Would you like to know more? Feel free to contact us!

Dit artikel werd gepubliceerd in het kader van het BBBC-project, met steun van de Belgische FOD Economie.