A new dimension in product design

Ultrashort pulse lasers can modify surfaces to give them new properties or functionalities such as friction, water repellency, anti-bacterial action or higher heat release thanks to improved radiation. They offer many advantages over conventional coatings and their application potential seems endless. Time for an introduction!

What are ultrashort pulse lasers?

Ultrashort pulse lasers are lasers that emit very short pulses lasting a few femtoseconds to picoseconds (a femtosecond is one millionth of a billionth of a second, a picosecond is one thousandth of a billionth of a second). These lasers have a very high peak power, which means that they can transfer a huge amount of energy in a very short time. This makes them ideal for machining materials on the nano- and microscale, without generating much heat or damaging the material.

How can ultrashort pulse lasers functionalise surfaces?

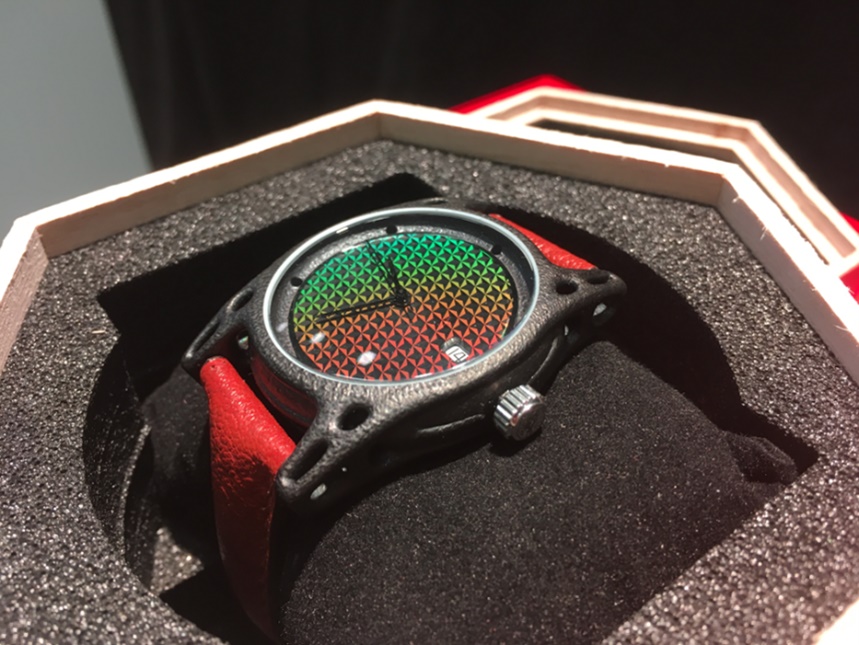

Ultra-short pulse lasers can functionalise surfaces by applying micro- or nanostructures that influence the interaction with light, liquids, gases or other materials. A number of different functionalities can be created by varying the shape, size, density and orientation of these structures. These include:

- Friction: by making the surface rougher or smoother, the friction between two materials can be increased or reduced. This can be useful, for example, for improving tyre grip, reducing the wear of machine parts or lessening the drag of aircraft.

- Water repellency: by covering the surface with small cones or pillars that resemble the structure of a lotus leaf, the surface can be made water-repellent or hydrophobic. As a result, water droplets roll off the surface easily, keeping it clean and dry. This can be useful, for example, for preventing corrosion, reducing ice formation or improving hygiene.

- Anti-bacterial action: creating sharp points or spikes on the surface that resemble the structure of a dragonfly wing enables the surface to kill or repel bacteria. This is because the points or spikes puncture or damage the cell membranes of the bacteria, causing them to die or come away. This can be useful, for example, to prevent infections, promote healing or extend shelf life.

- Improving the absorption of light and/or increasing the emissivity of a surface by creating ultra-black textures. These structures capture the light and ensure that objects become very black, which helps in particular when it comes to preventing reflections and stray light in space instruments. It also ensures that more heat can be radiated by so-called black body radiation, which can make heat exchangers much more efficient and compact.

What are the advantages of ultrashort pulse lasers compared with classic coatings?

Ultrashort pulse lasers have a number of advantages compared with classic coatings:

- They are more environmentally friendly because they do not use chemicals or solvents that can be harmful to health or the environment.

- They are more durable because they do not add an extra layer that may flake, crack or wear. The functionality is directly integrated into the material itself, allowing it to retain its original strength and flexibility.

- They are more versatile because they can be applied to almost any material, regardless of shape, size, colour or texture. They can also be used to combine different functionalities on the same surface, or treat different areas of the surface in different ways, depending on the need.

What does the future hold for ultrashort pulse lasers as regards surface functionalisation?

Ultrashort pulse lasers are a promising technology for creating new and innovative materials with customised properties. They can revolutionize various sectors, such as the automotive, aerospace, biomedical, textile and packaging industries. They can also contribute towards solving global challenges, such as reducing energy consumption, improving water quality, combating diseases and promoting the circular economy. Ultra-short pulse lasers are a powerful tool for designing materials with a new dimension: surface functionality.

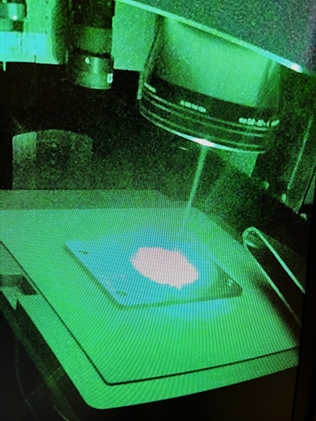

How can ultrashort pulse lasers be used in micromanufacturing?

Femtosecond laser micromachining technology is able to (selectively) remove microscopic layers from surfaces, without heating or damaging the main body. Femto lasers offer unprecedented benefits compared to classic lasers for micromachining processes such as: laser marking, laser engraving, micro/nanomachining (cutting, milling, drilling, polishing) and laser (selective) thin film removal.

Typical areas of application include microelectronics, medical equipment, optics, microfluidics, precision mechanics, tribology and microtooling.

ng.

Want to know more or want to start working with this technology?

This article was published as part of the BBBC project, with support of the Belgian FPS Economy.