New laser texturing devices, more versatile applications

In industrial applications, laser induced nano-textures optimise, alter, or renew the surface properties of a material. A new femto-second laser machine broadens the potential applications. Out of this range, this new chapter of Sirris's LIPSS research focuses on creating antibacterial surfaces.

Laser-Induced Periodic Surface Structures (LIPSS) uses laser technology to apply specific textures to a material’s surface. Femtolasers emit ultra-short laser pulses to texture an entire surface without causing heat damage. These lasers have a very high peak power, transferring huge amounts of energy in a very short time.

This single-step process is relatively simple and robust. By means of femtosecond laser machining, it meets the industrial demands for cost efficiency, reliability, and productivity reaching scales on the order of m2/s. LIPSS is a repeatable process, the use of different wavelengths and beam polarization will further determine the spatial characteristics of the nanostructures, controlling their orientation and period [1].

Laser shooting for advanced users

Different laser parameters create different patterns that work best with specific materials and applications. Exactly how this works is still a subject of scientific debate, but what’s clear is that LIPSS already has successful applications.

What can LIPSS do?

- Colouring or engraving: LIPSS can produce a text or a range of colours without the need for coatings or extra chemicals. The possibilities are vast, from promotional logo engravings to deep, black-coloured parts for aerospace. It has been applied to materials such as aluminium, stainless steel, titanium, and platinum.

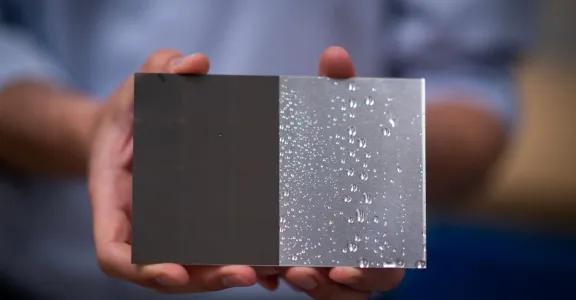

- Adapt friction or wear: by making a surface rougher or smoother, the friction between materials increases or decreases. Research also shows that materials with the right nanostructure are less sensitive to friction because the structure ensures that additives in lubricants work more effectively [4]. Usually, even better results are achieved when LIPSS is combined with micro-topography.

- Intervene on a biological level: in tissue engineering, nano topography is associated with promoting the process of cell differentiation, migration and proliferation.

- It accelerates wound healing and enhances osseointegration [2] — the extent to which an artificial implant connects with living bone.

- LIPSS also impacts a material’s antibacterial effects. By creating nano-ripples on a surface, the adhesion of bacteria and biofilm formation decreases [3]. This offers many medical or industrial applications. Dental or other implants, pre-treated with a LIPSS structure, gain an antibacterial advantage boost, reducing the risk of infections.[3]

LIPSS also yields favourable results in various technical applications, including optical (reflection, absorption, luminescence), electrical, and biomimetic structuring (for example, anti-icing in aerospace applications) and much more.

Will femtolasers shoot your sector into the future?

Ultra-short pulsed lasers or femtolasers are a promising technology for developing innovative materials with customized properties. They hold groundbreaking potential in sectors such as automotive, aerospace, biomedics and packaging.

Furthermore, they can help address global challenges, such as reducing energy consumption, improving water quality, combating diseases, and promoting the circular economy. These lasers offer a powerful means of designing materials with a new dimension: surface functionality.

LIPSS technology is applicable to a variety of materials, including metals, semiconductors, dielectrics, polymers, and composites. When laser-induced nano-structures are layered on top of micro-structures, they create “hierarchical structures”. This combination of nano and micro-structures further enhances the surface’s functional properties.”

New equipment, new research horizons

At Sirris, we are proud to announce a new chapter in LIPSS research in collaboration with Thor Park. With a new femtosecond laser device operating at various wavelengths, a new range of research possibilities has opened. More controlled texture changes are now possible through visible and ultraviolet wavelengths.

We have selected the creation of antibacterial surfaces as the starting point for this new research phase. An ongoing analysis is already examining the effects on biofilm formation and the effectiveness of bacterial removal. The results of this analysis will be available soon.

This article was published as part of the BBBC project, with support of the Belgian FPS Economy.

Curious about what femtolasers can offer in your sector?