Functional biopolymer coatings

Nanocelluloses are emerging as natural materials with favourable properties for coating industry and can conveniently be applied by spraying technology. The nanocellulose materials are reactive and mostly need chemical modification to obtain additional functionalities such as resistance against water or bacteria. Alternatively, adding specific surface textures to the coatings through physical processes can also enhance their properties. This why Sirris has successfully combined its expertise in coating application and surface functionalisation in a feasibility study on femtosecond laser texturing of sprayed nanocellulose coatings.

The study, which has recently been published in a world-renown scientific journal, Carbohydrate Polymers, shows potential for managing surface properties of soft coatings for interaction with water or anti-bacterial effects. For the first time, Sirris researchers were able to demonstrate how femtosecond laser texturing of soft biopolymer coatings can be used as a high-throughput method for surface patterning.

Nanocellulose in coatings and functional devices

Cellulose nanofibres (CNF) or cellulose nanocrystals (CNC) are a family of technically engineered nanomaterials typically suited for functional coatings, with intrinsic hydrophilic properties, resulting in self-cleaning, biocompatibility and biodegradability. The cellulose materials are most abundantly available biopolymers on earth and originate from primary renewable sources such as wood, annual crops, bacteria or algae. In viewpoint of a circular economy, the nanocelluloses can be more interestingly produced from residual side-streams of agricultural products, industrial sludge and waste, or pulp and paper residuals that are no longer suited for recycling mills.

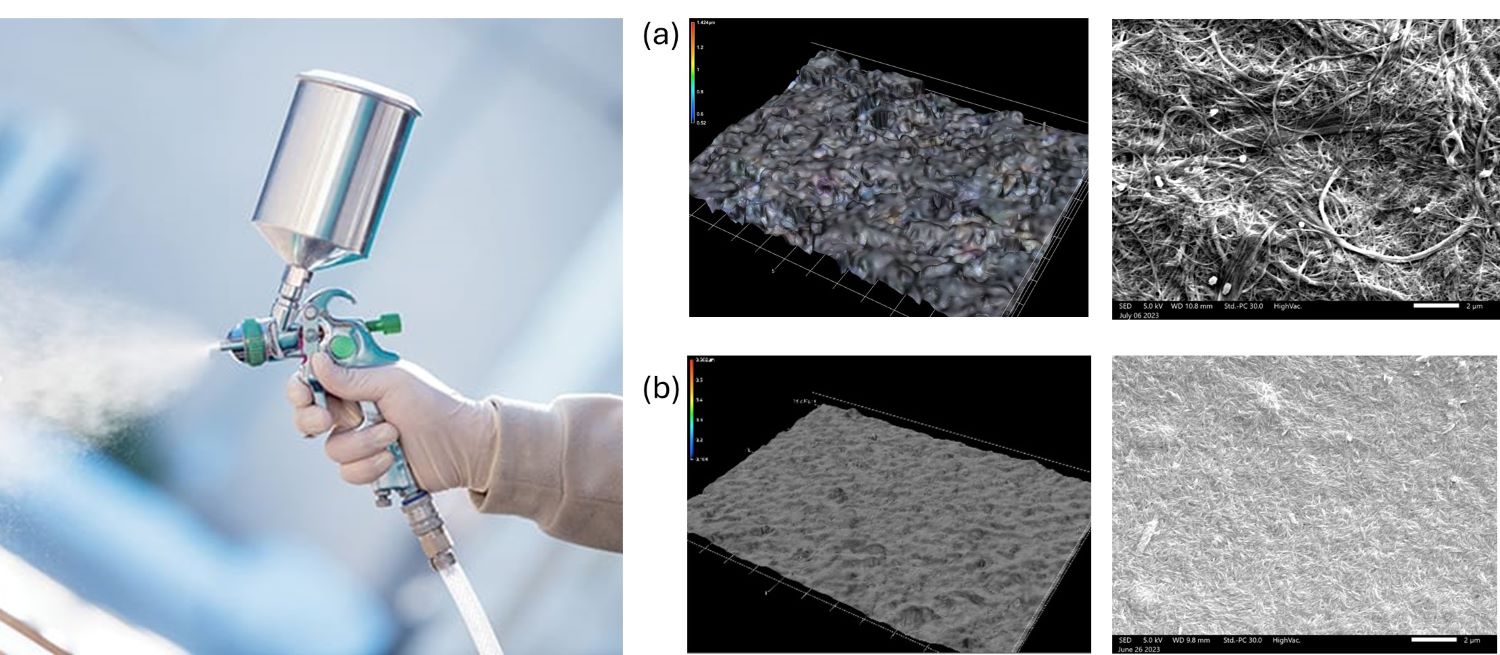

While synthesis and structure-property relationships of nanocellulose materials are mastered and sustainable production methods are optimised for energy savings and recovery, several grades became recently available at industrial scale. Owing to suitable rheological properties with shear-thinning, the spray-coating is a preferred technology for application at large-scale. The deposition of nanocellulose coatings of CNF and CNC through industrial spraying processes can be well controlled (Figure 1).

The hygroscopic behaviour and optical properties of nanocellulose coatings are relevant in analytical microfluidic devices, photonic materials, optical devices, solar cells, catalysts and devices for artificial photosynthesis, photochemical cells, membranes, anti-friction coatings and lubricants. In combination with well-defined control on roughness and porosity, nanocellulose coatings may serve as absorbents, moisture buffer or bio-scaffolds with targeted bacterial growth and cell interactions.

However, the advanced coating performance with management of surface wetting and directional control of liquid transport requires better surface design and economically feasible replication of surface architectures with micrometre-scale dimensions.

Patterning of nanocellulose surfaces

The patterning of nanocellulose coatings has been approached to create biomimetic features with hierarchical surface roughness and better control over porosity. Different patterning techniques following bottom-up and top-down approaches have been applied to natural polymers or related paper products at least on laboratory scale, but it has been recognised that technological efforts for microtexturing nanocellulose surfaces at larger scale are lacking behind.

The microtextures on nanocellulose surfaces can primarily be created through bottom-up organisation, where self-assembly is controlled by intermolecular forces and surface interactions, either in presence of mechanical load, magnetic fields or electrostatic fields. The more complex hierarchical structures with oriented nanofibrils and high roughness of nanocellulose coatings were obtained through electrophoretic deposition. Alternatively, the control of evaporation time during drying of a nanocellulose suspension and differential evaporation over the surface of a nanocellulose film resulted in local surface patterns with optical features.

The top-down patterning of nanocellulose coatings relies on batch processes such as micro-embossing or wet stamping, where, e.g., periodically wrinkled elastomeric substrates prepared by stretching and oxidation can be used as template to transfer aligned nanocellulose patterns. This technology can be up-scaled towards roll-to-roll manufacturing or flexo-printing, in combination with dip- and spray-coating of the nanocellulose dispersion onto a template. The roll-to-roll nano-imprint lithography was further developed as a high-throughput method for the replication of periodical patterns with micropillars onto nanocellulose films with control of the roughness profile and specific optical features.

However, current methods require precise control of the nanocellulose fluid flow with strict rheological features, control of dewatering, or additives to modulate the mechanical coating properties. Also the fabrication of replica moulds for lithography should be economically viable and requires high sample volumes with low flexibility. More direct machining methods with low processing cost, high throughput, flexibility and micrometre precision are needed in order to enhance industrial upscaling.

Exploring femtosecond laser texturing for soft surfaces

Laser texturing has recently been identified as an excellent technology to modify surface wettability of various materials due to the relative simplicity and robustness of the results, together with the widespread availability of affordable industrial laser sources. Over past years, Sirris has built experience with the technology for functionalisation of hard metal or ceramic surfaces, introducing friction control, wear reduction, colour transitions or superhydrophobicity.

The ultra-short-pulsed (i.e., femtosecond) laser texturing, in particular, can also be applied to soft polymer substrates or paints and coatings, as it offers clean processing without thermal damage. Although femtosecond laser texturing has recently evolved into a novel, mature and robust technology with promising results, it was not yet applied for patterning nanocellulose coatings.

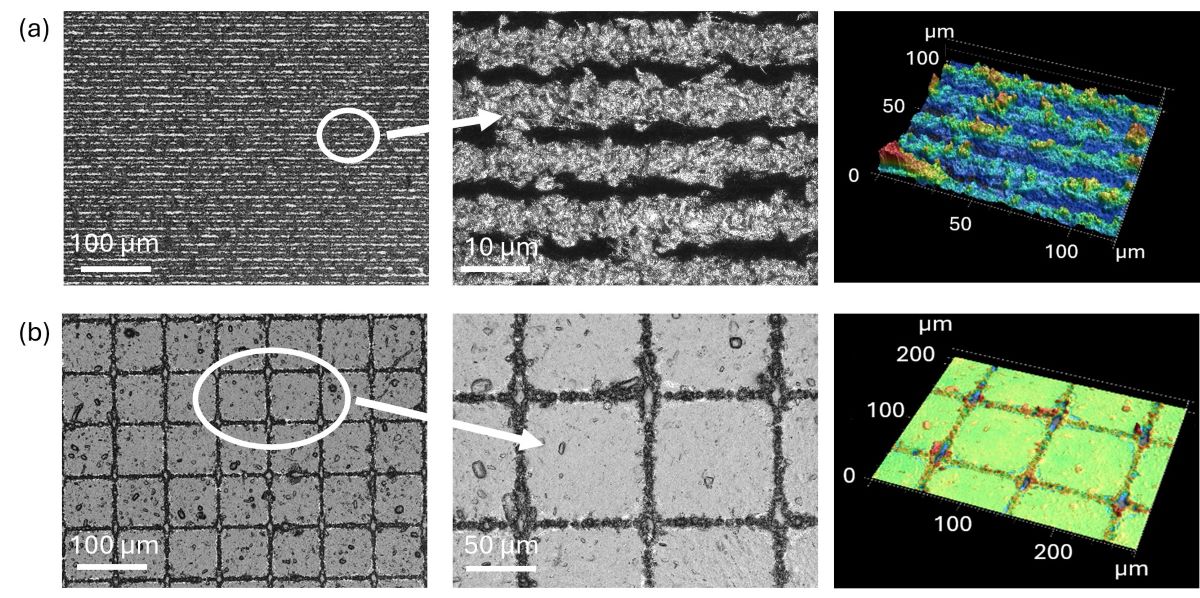

In a recently published study by Sirris researchers, the patterning of spray-coated nanocellulose coatings by femtosecond laser texturing was presented as a novel technique to provide functional nanocellulose coatings. In particular, the operational processing window of laser pulse rates and power settings was determined for creating one- and two-dimensional surface patterns (Figure 2). The secure control of processing parameters was more critical, compared to hard surfaces, and the very small variations in setting parameters provide a tool to alter pattern features and morphologies of the nanocellulose surface patterns. Depending on the origin of the nanocellulose coating with cellulose nanofibres (CNF) or cellulose nanocrystals (CNC), however, the mechanical properties of the coating may differ, but finally a good correlation between coating density and laser ablation conditions was found.

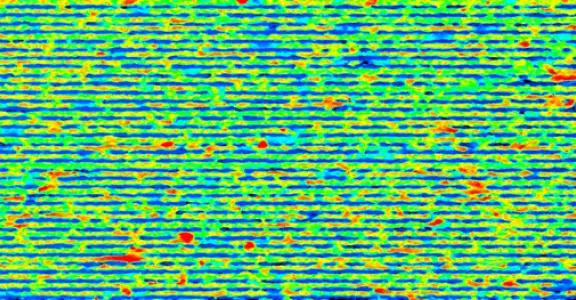

However, the main challenge to overcome was the high intrinsic surface roughness of the nanocellulose coatings, that needs to be balanced against processing conditions in order to provide long-range homogeneity in the surface patterns.

Outlook and future perspectives

The work has demonstrated that femtosecond laser texturing can be applied as an industrially scalable technology for patterning of nanocellulose coatings, which may open new opportunities for surface engineering at high throughput scale in a plethora of application domains where tuning of surface hydrophilicity is required. In particular, the way water droplets can be stabilised onto the patterned surfaces, while retaining the hydrophilic characteristics of the nanocellulose coating, has been evaluated. In a current approach, the laser texturing of nanocellulose coatings is further combined with chemical surface modification to specifically tune wettability or introduce superhydrophobic and anti-bacterial surface properties.

Read the full text of the feasibility study.

Sirris is further involved in the design of anti-microbial surfaces based on nanocellulose coatings, where both chemical functionalisation and surface patterning of the nanocellulose materials are combined. Sirris is a partner in the European project Triple-A-COAT, where antimicrobial, antifungal and antiviral coatings based on nanocellulose are developed for use in high-traffic surfaces. The role of surface patterning in anti-microbial activity is also investigated in the BBBC (Belgium Builds Back Circular) project on biomimetic design of surface functionalities through femtosecond laser texturing.

This article was published as part of the BBBC project, with support of the Belgian FPS Economy.

Interested in our research on surface coating and functionalization?