Introducing AMR/AGV in a production environment - Part 3

Logistics operations add little value, but they are necessary to keep production on track. After all, materials, components and tools need to be in the right place at the right time.

In this four-part blog series, we want to share our experiences concerning the role and implementation of autonomous vehicles. In this third part, we take a close look at the fleet manager.

Moving products and resources efficiently

The core tasks of fleet management software for AMRs are:

- Centralised monitoring: fleet management software provides real-time insight into the status and location of each AMR in the fleet. This allows you to monitor the AMRs’ movements, track progress with tasks and identify any problems or delays.

- Task assignment and planning: the software facilitates the assignment of tasks to AMRs on the basis of priority, location and availability.

- Route optimisation: fleet management software analyses layouts, traffic patterns and task requirements to optimise AMR routes.

- Collision avoidance: AMR fleet management software includes algorithms to prevent collisions and ensure safe navigation in dynamic warehouses. The software monitors AMR movements in real time and automatically adjusts routes.

- Maintenance and diagnostics: the software monitors the performance and health of AMRs, provides alerts for routine maintenance tasks and identifies potential problems before they escalate. This proactive approach to maintenance helps minimise downtime and extend the life of AMRs within the fleet.

- Integration with warehouse management systems (WMS): fleet management software integrates seamlessly with WMS and other business systems to exchange data and streamline warehouse operations.

- Reporting and analysis: the software generates reports and analyses on AMR performance, productivity and efficiency.

Fleet manager within the demonstrator

Meili is an online system where the starting point is inputting the production environment, just like with other fleet management systems. This is done by letting the AMR explore the environment and uploading the data.

The fictitious production company Fiko uses the Meili fleet manager for two reasons. Firstly, the demonstrator will only contain two AMRs, so a light fleet management structure is sufficient. Secondly Meili positions itself on the market as a solution that controls AMRs from different manufacturers.

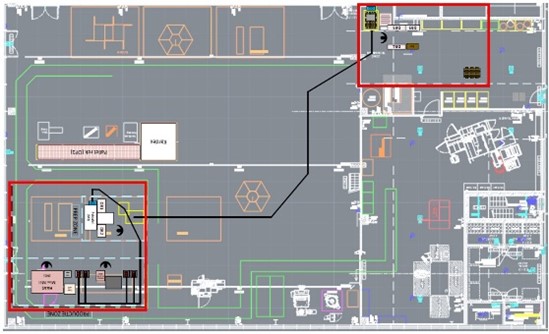

On the left below is the CAD drawing of the layout of the Sirris workshop at FacThory in Genk. The boxes outlined in red indicate the two production zones within the demonstrator: the warehouse at the top right and the machining zone at the bottom left. The figure on the right shows the layout as identified by the AMR and as applied in the Meili software.

|

The AMR’s theoretical lanes are also marked with black lines on the CAD drawing. The line between the two zones is the lane that the WEWO-AMRs with transport containers on a pallet carrier will take, while the lines within the machining zone show the lanes of the MiR-AMR. In the Meili software, the actual routes of the AMRs are shown as purple lines. In both drawings, there is a point in the machining zone where the routes of MiR and WEWO almost coincide. This point is where components are received from the warehouse and depart for processing. It serves as a test for the fleet management software, which must be able to anticipate a possible collision between the two AMRs.

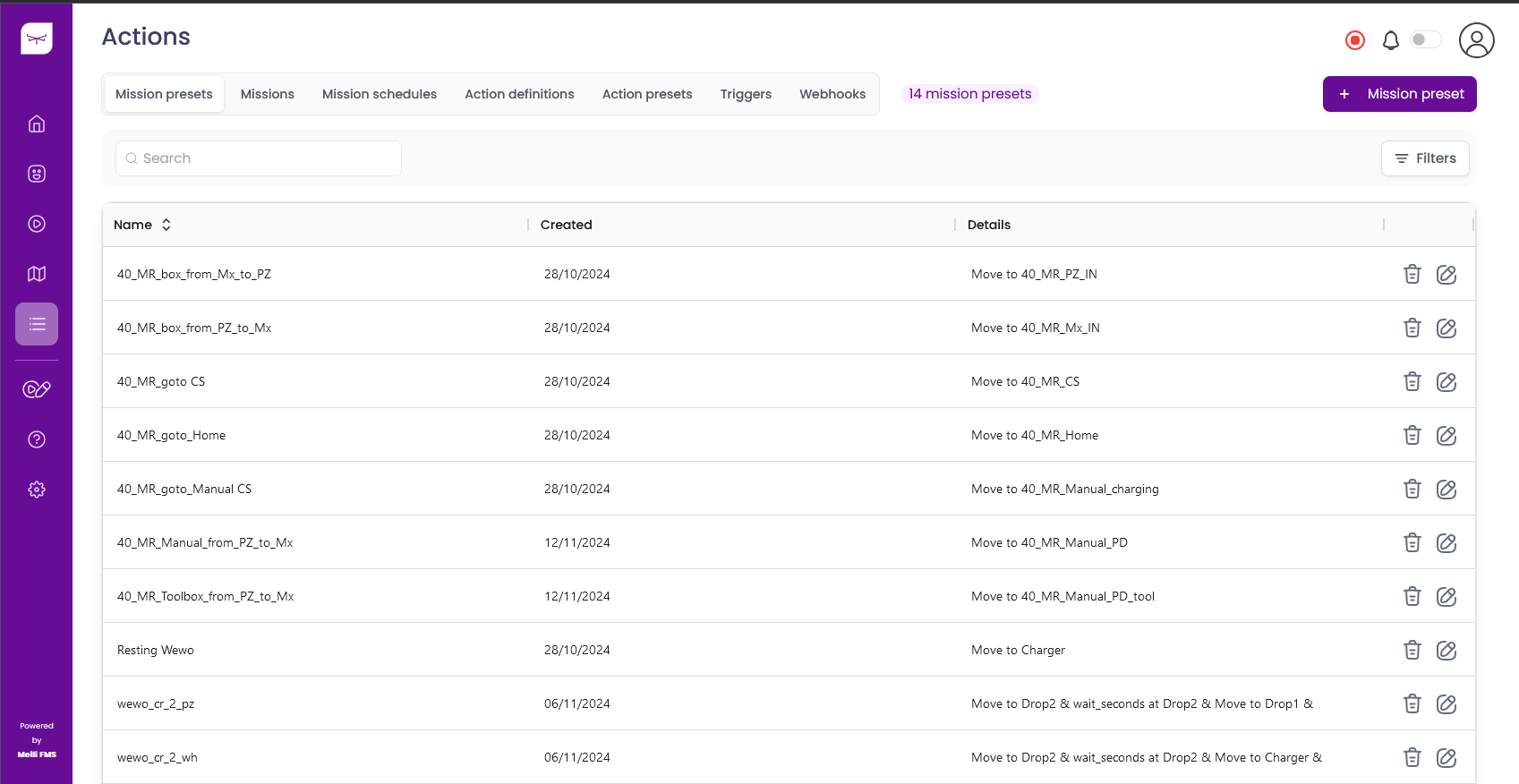

In the next phase of the fleet manager startup process, the logistical movements are defined. This means the ‘from A to B’ tasks that the different AMRs must carry out. In Meili, these are called missions. Supported by the MES software, they then set off individually. The actual control of and communication with the AMRs use a restAPI protocol.

Online dashboards provide an overview of all current and completed missions, so you can follow the movements of the different AMRs in real time.

|

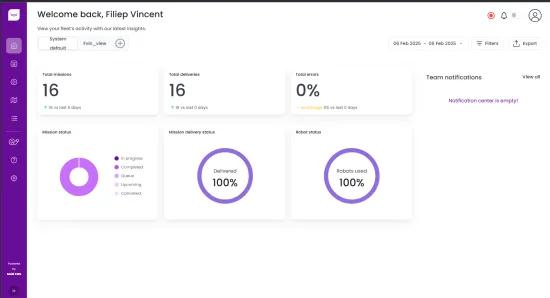

| Meili provides an analysis of the accuracy of execution and the efficient use of the AMRs. There is also an overview of all actions taken to anticipate a potential collision between AMRs. In this overview, we can see that both the WEWO and the MiR have been instructed to wait until the processing zone’s reception area is freely accessible. The Meili software thus detects potential problem situations in good time and takes appropriate anticipatory action. |

Collision avoidance

A fleet manager’s purpose is to guide a fleet of transport robots. There are (to cut a long story short) two possible implementation scenarios:

- full control by the fleet manager;

- the fleet manager sets tasks.

In the first scenario, the fleet manager will monitor and control the transport robot over the entire route. To make this possible, the transport robot defines successive zones and the fleet manager decides whether the next zone should be entered.

In the second scenario, the fleet manager will only call up pre-programmed missions or routes for the transport robot. The main difference between the two scenarios lies in whether or not the transport robot’s functionality. such as autonomously avoiding obstacles. can be used. The robot’s full functionality only remains in use in the second scenario.

The demonstrator implements the second scenario in which the fleet manager only calls up pre-programmed missions or routes, as it is necessary for the MiR to have the full built-in functionality available. For example, an internal signal in the control system activates the mounted roller conveyor when a loading or unloading point is being approached. The functionality to autonomously deviate from the pre-programmed route in order to avoid obstacles also remains active.

The WEWO’s restAPI means that a hybrid setup is possible, as the protocol activates all possible internal signals. The only drawback is that the fleet manager actually has to program them.

Although the fleet manager only calls up pre-programmed missions, the positioning of each transport robot is always present. On the basis of the robot’s position, the fleet manager will predict and avoid collisions. Each transport robot is given a safety perimeter. As soon as there is an overlap with the perimeter of another transport robot, priority rules apply. In the Meili fleet manager, production transport is given priority over warehouse transport. In practice, this means that if the WEWO (warehouse transport) arrives at the prep zone at the same time as the MiR (production transport), the WEWO will stop and give way.

This article is part of a four-part series on introducing AMR/AGV within a manufacturing environment. Would you like to read more? Discover our other articles in this series:

Part one | Choosing the most suitable production strategy >

Part two | Setting up a digital production environment >

Part four | Everything you need to know before starting an AGVsim project >