Introducing AMR/AGV in a production environment - Part 4

Logistics operations add little value, but they are necessary to keep production on track. After all, materials, components and tools need to be in the right place at the right time.

In this four-part blog series, we want to share our experiences concerning the role and implementation of autonomous vehicles.

In this fourth and final part, we look at the number of vehicles, the importance of this for logistics movements and the return on investment (ROI) you can expect.

AGVsim

An important factor in calculating the ROI of an AGV/AMR is the number of devices you need. Sirris has developed AGVsim for this purpose – a software application that helps businesses of all sizes to estimate this number. AGVsim does this in light of the specific task list in a given environment. It’s easy to use, yet the results are reliable.

How do I start an AGVsim project?

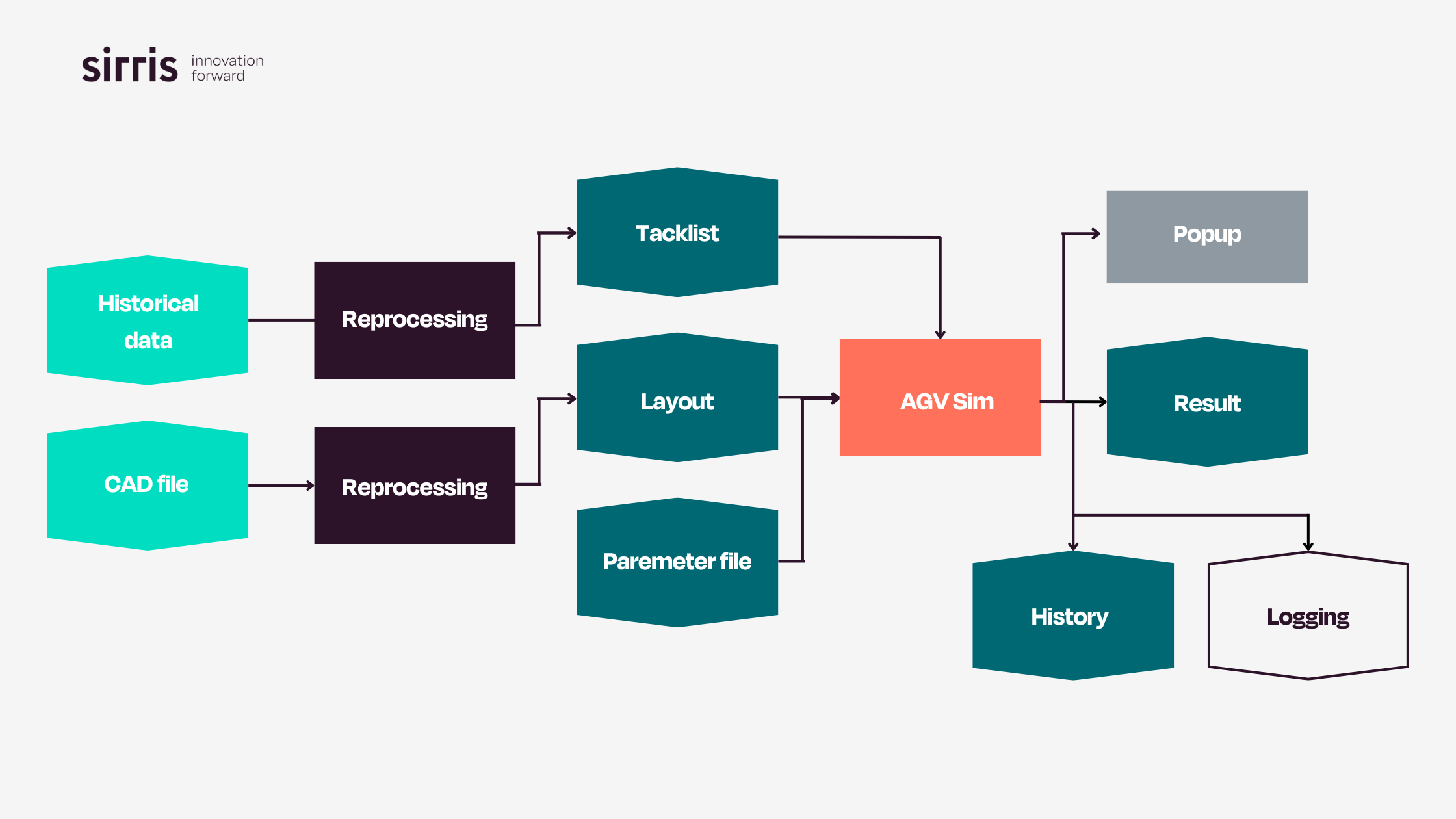

The input data for the application consists of three Excel files:

- Layout file

- Task list file

- Parameter file

The workflow is as follows:

- On the basis of a CAD file of the space, you can add colour to the layout file to indicate routes, machinery, stops and so on.

- You also draw up a list of transport operations, for example by using historical data from the ERP system.

- Finally, the parameter file enables you to set parameters for one or more AGV devices and the general operating parameters.

After the Excel files have been created, simply press ‘start’ to obtain an initial result after a few seconds. The simulation uses the set parameters to calculate how your choices affect the number of AGV devices needed.

Ease of use is very important, which is why AGVsim can also define scenarios. A scenario is a combination of the three files mentioned above, and it allows you to compare the results of different situations.

Typical problems where AGVsim can help

Starting from the three initial Excel files, you can calculate the occupancy rate (OR) of the ‘AGV system’. This means that you assign all tasks to one AGV.

You can then ask the following questions:

- What is the impact on the OR if I...

- increase or decrease the maximum AGV speed or acceleration?

- change the position of a machine?

- take a different path to get from A to B?

- split the tasks between two or more AGVs?

- have a battery that can be charged more quickly or has more autonomy?

- limit the AGVs’ capacity to cope with fluctuations in demand?

- What is the percentage of the arrival and departure time relative to the total task time?

- Can I reduce that percentage by choosing my home position better?

- What is the OR if I take the shortest defined path everywhere?

Get in Touch

If you are at the beginning of an AGV project and would like to use AGVsim for an initial estimate of the number of devices, contact us. We’ll be happy to help.

This article is part of a four-part series on introducing AMR/AGV within a manufacturing environment. Would you like to read more? Discover our other articles in this series:

Part one | Choosing the most suitable production strategy >