Technical production operators are often charged with an array of different logistics tasks, which can result in decreased productivity. By handing over these tasks to autonomous mobile robots (AMRs), technical operators will be able to once again focus on their core activities. Reach out to us and we’ll be happy to help you explore the potential of mobile robots that can optimize your production logistics.

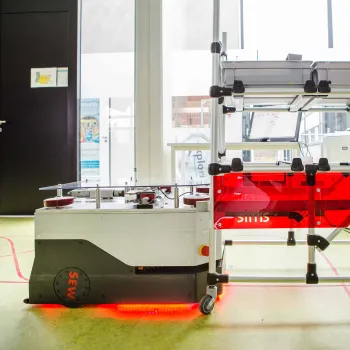

Mobile robots for production logistics

Driving flexible production logistics innovation

Operators walking around looking for material, transportation being performed manually, materials being stocked on the shop floor to avoid machines from running dry, and suboptimal planning resulting in downtime and material shortages… Does this sound familiar? If so, flexible automation with AMRs can take away a lot of frustration and boost your efficiency.

Technological advances create new opportunities

Recent technological advancements resulted in a break-through for autonomous mobile robots.

- AMRs can now manoeuvre accurately in production environments, thanks to a combination of autonomous movement and sensing, as well as increasingly accurate positioning technologies.

- AMRs can now handle material (semi-)automatically, e.g., by unloading machines, thanks to a variety of newly available cutting-edge modules.

- External sensors provide additional real-time information that increases the performance and accuracy of the AMR.

- Digital platforms make it possible to orchestrate different AMRs on the production floor.

As a result of these advances, AMRs can now be used not just in warehouses, but also in more complex production environments. At Sirris, we have all the expertise to help you on your way.

Achieving your best production logistics concept

Many questions arise when you want to automate your production logistics. Apart from the technological decisions (AMR, the best modules for material handling, automation at a machine/cell level), you need to pay careful attention to defining your best logistics concept as well: defining the flows, rearranging the production layout for optimal flow, assigning tasks to the AMR and operators, etc. At any point, you should consider both the technological and economic feasibility (ROI). At Sirris, we are happy to help you with navigating this process.

Autonomous mobile robots: 4 reasons why

Wide range of applications

AMRs can take over numerous production logistics tasks faster and more efficiently than ever. Thanks to additional sensing and motion capabilities, they are no longer restricted to the structured flows and large pathways of warehouses; they can also handle more chaotic environments like production shop floors.

Best fit for logistics

Even though AMRs are not ‘one size fits all’, dedicated cutting-edge modules ensure an optimal fit to your logistics concept. As artificial intelligence advances, problem-solving and learning analytics will enable AMRs to be even more responsive to live interactions such as obstacles and temporarily blocked zones.

Safety as top priority

By using built-in sensors, laser scanners and intelligent algorithms, autonomous mobile robots can detect (human) obstacles and adjust their route accordingly. This allows for a safe, collaborative and productive environment between AMRs and warehouse workers.

Excellent scalability

AMRs give you more options to meet capacity demands and deal with unexpected peaks or drops. For example, you can easily adjust the number of hours they’re in operation each day. Moreover, with real-time monitoring, they put dynamic schedules within arm’s reach.

Inspiring articles

Immerse yourself in the world of mobile robot applications

Our expert, Filiep Vincent, will gladly show you the ropes.