In the INSIDE Metal AM project Sirris, CRM and BIL investigated the technological and economical feasibility of 3D printing with steel. Next to understanding all the opportunities for redesign and added value, there are also economical and technical questions to be answered. It was the goal of the INSIDE Metal AM project to provide a foothold for Belgian companies considering the use of 3D printing with steel. The most important conclusions from this project have now been summarised in a white paper, free to download.

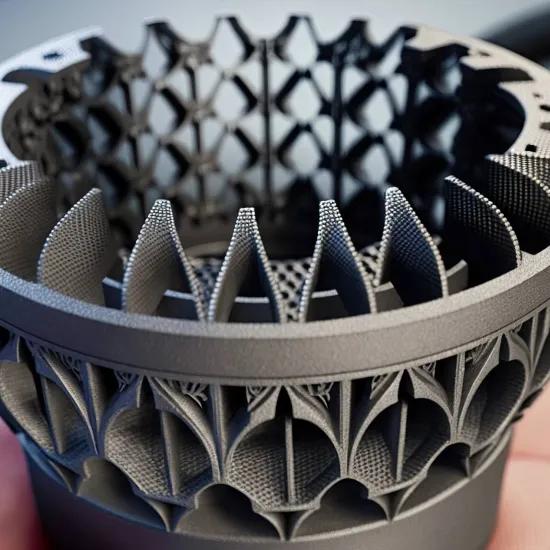

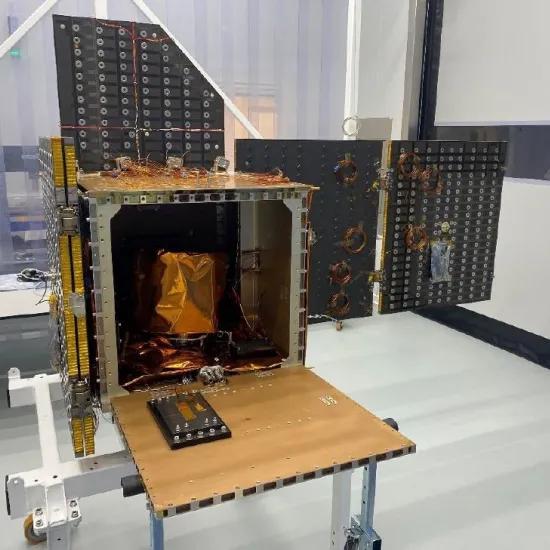

You think 3D printing with steels could be an innovative and efficient technology for your company? Considering an investment in additive manufacturing equipment or start exploring in collaboration with a printing service provider? Often these questions are the start of a journey towards the potential use of additive manufacturing (AM). As part of the INSIDE Metal AM project, a number of demos were produced that can serve to inspire you further. These were already introduced in an earlier post. Once you start digging deeper you will, however, realise there is a lot more to it. The INSIDE metal AM project doesn’t answer all the business and technology related questions you might have on this rapidly evolving subject. It does however cover many key aspects and activities relevant for current and future users of metal AM.

Three different technologies have been covered in the project: laser powder bed fusion (L-PBF), laser metal deposition (LMD) and wire arc additive manufacturing (WAAM). Based on the findings of the project, a white paper was prepared in Q&A style. Some of the questions we have tried to answer are:

- What steels are available for 3D printing?

- How can the quality of raw materials be controlled and maintained?

- How do process parameters need to be selected and how do they impact the material properties?

- What is the impact/importance of heat treatment after 3D printing?

- What is the achievable surface roughness after post-processing and does the surface roughness influence the part properties?

Although it is not possible to provide a completely comprehensive answer to these questions, the white paper provides a starting point for those who want to learn more about 3D printing with steel. The project partners welcome any further questions you might have and are looking forward to support you on your journey towards incorporation of AM in your processes.

This project has been completed with the support of Vlaio and the Strategic Initiative Materials (SIM).

]]>