The PONAMP project, a joint initiative of R&D company Materia Nova and Sirris that ran from 2019 to 2021, resulted in several material innovations. One of its key achievements is the modification of the widely used aluminum alloy 7075 (AA7075). Through in-situ micro-alloying, the material’s mechanical properties could be greatly enhanced. Here’s how.

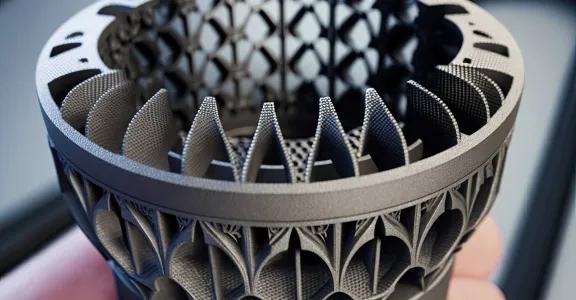

AA7075 is widely used in aerospace and other industries because of its strength. However, the material has an important drawback: it can’t be used in additive manufacturing without cracks appearing at the heart of the material. This restricts its use in more complex manufacturing applications.

Powder functionalization by PVD

With the PONAMP project, Sirris and Materia Nova wanted to explore the benefits of powder functionalization by physical vapor deposition or PVD. This coating process transfers material at the atomic level.

More specifically, the focus was on two main innovations:

- Enhancing the laser absorption of copper powder to enable more efficient 3D-printing processes without compromising the material’s electrical and thermal conductivity.

- Modifying AA7075 through micro-alloying to improve its mechanical properties and make it printable.

A promising new coating

By using a novel coating strategy that involved non-rare earth elements, researchers managed to effectively block hot cracking and protect the powder from contamination. The results were immediately promising: the modified AA7075 prints very easily and has greater recycling and repair potential. Under the Weldalam project, further tests showed that this coating could effectively solve common welding difficulties with aluminum alloys in additive manufacturing.

Joint patent

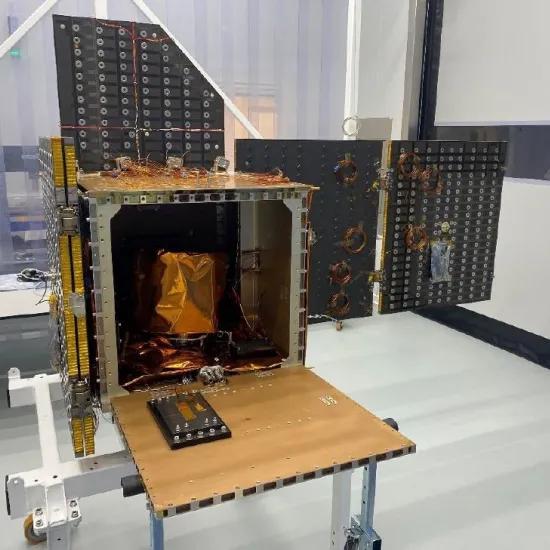

And that's not all. Thanks to the validation of alloys commonly used for structural applications, such as AA7075, aerospace companies will need fewer qualifications to adopt these special manufacturing techniques. This approach also enables the reuse of common but non-printable aluminum types with LB-LPBF additive technology. As these advancements sparked potential interest from key industry players like the European Space Agency (ESA) looking for greater operational efficiency and cost-effectiveness, Materia Nova and Sirris decided to file a joint patent.

Our experts for this innovation project

Annual Report 2023: Another year of innovation!In 2023, we didn't just adapt, we innovated and elevated! From boosting innovation services to diving deep into energy transition and manufacturing, we've been busy. We completed over 1.200 innovation projects and highlighted 13 industrial cases in the annual report. And let's not forget our leap into Generative AI, which is a game-changer. |