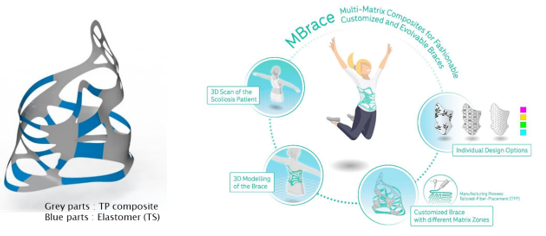

MBrace | Multi-Matrix Composites for Fashionable, Customized and Evolvable Braces

MBrace develops original techniques based on tailored fibre placement technology, towards the design of an aesthetic and innovative orthopaedic brace for the medical treatment of spine displacement (scoliosis) to ensure patient comfort.

Context

Every year, 22 million Europeans are treated for scoliosis. Non-invasive treatment at child’s age is the preferred option. The brace confines the upper body in a rigid polyethylene shell for approx. 23 hours a day, 7 days a week, from the start of puberty until the end of growth. It is tedious and exhausting, especially in the heat of summer. Despite the restrictions, brace therapy is the most effective treatment of scoliosis, showing satisfactory results for 75 % of patients. The only existing alternative in case of a severe scoliosis is highly invasive surgery along the entire spine. Subsequently, restrictions in every aspect of daily life are accepted.

Goal and results

The MBrace project aims to significantly improve the well-being of these young patients. The project will develop original techniques based on tailored fibre placement technology, towards the design of an aesthetic and innovative orthopaedic brace for the medical treatment of spine displacement (scoliosis) and to introduce the mineral fibre produced by Isomatex as the indispensable reinforcement feature to ensure patient comfort.

In concrete terms, we can expect:

- structure design of optimised organic geometry, produced thanks to tailored fibre placement, and associating rigid thermoplastic (TP) inserts and elastomer connections,

- a significant reduction in mass, hence a reduction in load for the patient,

- considerable improvement in freedom of movement and aesthetics,

- a targeted biomechanical effect of the brace structure for improved therapy,

- possible adaptation of the biomechanical effect through small readjustments to insert form during a post-correction phase.

Approach

For Isomatex, the aim of this project is to optimise compatible sizing with selected resins, to ensure sustainable brace performance. For Sirris, this project will aim to develop and improve the different innovative manufacturing technologies required, based on easily tailored tooling solutions. This includes consolidating the various thermoplastic inserts of the brace and overall infusion, by means of a thermoset elastomer resin, to finalise the product and make it comfortable.

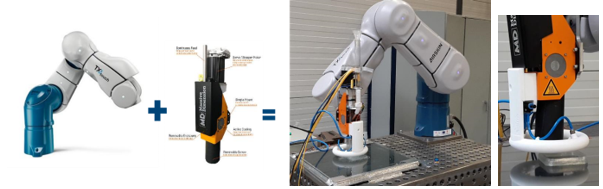

To achieve this aim, specific technologies and tooling will need to be developed, produced and improved, at a reasonable cost. To do so, Freeform 3D printing will serve as the support technology. As illustrated, it results from the combination of an extruder and a robotic arm.

Since the thermoplastic material is reversible, a specific study will be conducted on the post-correction of the insert form, in an aim to adapt the brace design in line with ongoing therapy.

Funding

- Funding framework: European Research Area Networks M-era.Net