Usability and limitations of portable scanners

What materials is a product, part or subcomponent made of? This crucial information is sometimes missing when exploring or applying circular practices such as refurbishment and recycling, while we would actually prefer to know this information immediately and on-site. Sirris mapped out the measurement techniques and portable devices (scanners), with a focus on plastics. Discover it here!

How to select a portable scanner for your needs?

To characterise products, material composition and structure, a wide range of techniques and measurement methods is available, each with their scope of application (material classes, information delivered, accuracy, speed, etc.) and specific constraints (sample preparation and extent to which it damages the product, cost, expertise required, etc.). Analysing and characterising materials is a discipline in itself! The associated hardware spans a wide spectrum, from costly, room-sized systems and rugged industrial sensors used for real-time process control, to compact, portable scanners. Ongoing advancements in miniaturisation, AI-driven data processing, and cloud-based software solutions are expanding the capabilities and variety of portable scanners.

For immediate material identification, several additional prerequisites must be considered:

- Portable devices (‘scanner’), with reduced size/weight and ideally autonomous energy supply.

- Minimum sample preparation.

- Rapid analyses.

- Spatial resolution: size of the measured surface and penetration depth tailored to the sample's variability and the specific information required.

- Ideally, the measurement process should demand minimal expertise, featuring straightforward calibration, easy selection of measurement settings and processing algorithms, and ample support for visualising and interpreting the results.

Choosing a scanner to identify plastics: our experiences

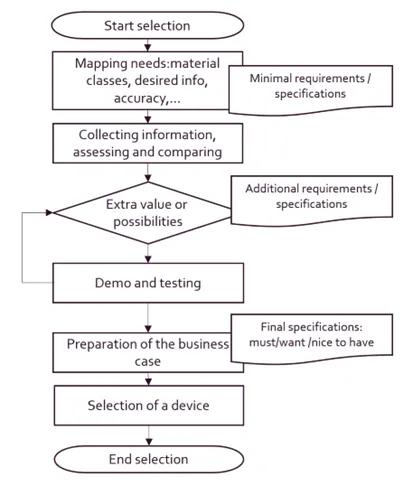

As part of the Planum project (see box), we investigated which portable devices are capable of identifying plastic materials. In doing so, we broadly followed the process visualised in the flowchart below (Figure 1).

Our need is to recognise the type of plastic rather than obtaining a full quantitative analysis (chemical composition with all additives). This may involve parts made of plastics, composites, recyclate blends .... Three measurement techniques may qualify for portable scanners: NIR, FTIR and XRF. Table 1 summarises their main features, advantages and disadvantages. Since our primary requirement is identifying molecular composition (such as plastic types) rather than elemental composition (chemical elements), we opted against XRF and chose to focus on NIR and FTIR technologies.

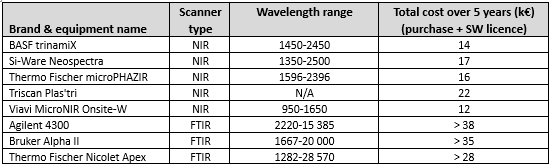

We then mapped out the market offering for portable NIR and FTIR scanners (see Table 2).

We had the following experiences in this regard:

- Mapping the entire market comprehensively is a challenging task. We have focused on brands and devices available and supported in Belgium, often through local distributors. The market offering is dynamic, with frequent changes including new manufacturers, updates to existing devices, new models, and handheld versions of industrial quality control instruments.

- Objectively mapping the device performance requires a large-scale comparative study. The performance of these devices varies based on several factors, including the specific measurement task, the type of plastic (e.g., parts, granulate, or recyclate blend), the heterogeneity of the sample, and the device’s technology and specifications (such as light source, optics, detector, wavelength range, and signal-to-noise ratio), as well as the methods used for processing and interpreting the measurements.

- In terms of data processing, there is typically little information available about the algorithms used. In addition, the integration of a rich database of validated spectra is very important. Again, it is difficult to obtain objective data on this. Some manufacturers manage their datasets internally, while others rely on open communities where users contribute to and enhance the dataset systematically. There are also instances where users can create and safeguard their own datasets.

- Scientific literature occasionally includes comparisons of portable scanners for specific measurement tasks (see sources). However, these studies often feature different selections of scanners and varying comparison criteria.

To estimate the total user cost of these devices, we considered the following factors:

- Acquisition costs

- Licence fees for using the processing software and associated database

- Operator costs: speed, convenience and level of operator expertise required. Most devices are user-friendly and can be used after a short training. FTIR devices in particular may require more specific expertise and experience in materials analysis for meaningful interpretation of measurement data. Since it is very difficult to objectively estimate these operator costs without having the devices, we did not explicitly include this aspect in our evaluation.

Which device did we choose?

We contacted and conducted demonstrations with the manufacturers and distributors of the devices from Table 2. Without proceeding to a large-scale comparative study, we finally decided, based on the available information, initial experience and cost, to purchase a Viavi microNIR onsite-W. We are now using the device and its accompanying Nirlab-database in full and are building experience and expertise in identifying plastics on the fly (i.e. on-site and directly). We will report on this in a follow-up article soon.

Interested to learn more about building knowledge on portable scanners or to test our selected device firsthand?

Maximising the reuse and recycling of parts and materials from decommissioned aircraft is the main goal of the Planum project, led by Sabena Engineering. In this initiative, Sirris is focused on the revalorisation of plastic materials.

The aircrafts being decommissioned today are typically several decades old. There is often insufficient documentation available on the types of materials (polymers and composites) used in both the structural parts and the interior of the aircraft. Additionally, since the cabins may have been renovated or replaced over time, reliable and validated information is frequently lacking. As part of the Planum project, Sirris is exploring which solutions are available and practically applicable for effectively identifying polymer materials on the fly.

More information on the project (in French)