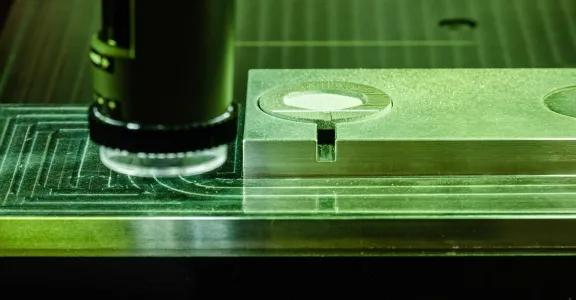

Lasers are used in different ways to cut material. New technologies such as ultrashort pulsed (USL) lasers can cut transparent materials in a new way: 'stealth dicing'. Ultrashort pulsed lasers - femtosecond lasers - also have the advantage that they don’t melt the material. The material is powdered, without heating the surrounding material. We briefly outline the technology and application.

Powdering a complete cut with ultrashort pulsed lasers is possible, but it is slow and you also lose surface area. Using a femtosecond laser here has the advantage that the "heat affected zone" around it remains minimal.

In case the material is transparent and brittle, focus the spot in the material to create defects at different depths along the cutting direction (see figure below, a, b, c, d). The material then breaks along these defects. Because a defect is generated internally, this technique is called 'stealth dicing'. Ultrashort pulsed lasers are suitable for this purpose, as they have a sufficiently high intensity as the energy is compressed in the short time span of the pulse. The prerequisite for this is that the material is transparent to the wavelength of light used, as well as brittle, so that it breaks easily.

As illustrated in Figures a to d below, the zone in the material that is exposed becomes longer and narrower. In the figure a (strongly focused), one shifts the depth of focus between the pulses, so that discrete defects appear in the material. First, the deepest defects are made, in order to prevent light scattering at the defects above.

In figure b below (top right), there is an overlap and a long, non-uniform defect is generated. If one switches to a loose focus according to the thickness of the material, one can generate a more uniform defect with one pulse over a larger distance (see figure c).

Finally, as shown in figure d, with the help of special lenses (e.g. axicon) the light pulse can be made to interfere with itself ('Bessel beam'). This distributes the light pulse over a large depth (1 mm), but over a very small area (diameter of 1 µm), so that there is still enough energy to generate a defect over a distance of 1 mm.

This causes small cracks to appear over the almost entire thickness of the material. Knowing that the pulse frequency is typically around 1,000,000 per second, this ensures cutting speeds of up to 1 m/sec.

A prerequisite is that the material is brittle and transparent. After all, the light must propagate through the material to the point of focus. Today, there are already USP lasers and lenses, with different wavelengths: 200-2.000 nm. Compare: The wavelength of visible light is between 400-700 nm, which means that even though you cannot see through a material, it may still be transparent to other wavelengths.

Application and potential

The technique of ultrashort pulsed lasers is today used worldwide to cut glass for optical displays. Other materials, such as sapphire and the plastic PMMA, are under investigation.

There has also been progress in terms of the thickness of the material: the thickness of the material is typically a few millimetres, but recently it was possible to demonstrate the cutting of 1 cm thick glass at research level.

Do current laser solutions not cut cleanly enough for your application or do you want to know more about the possibilities of femtosecond lasers for cutting your material? Then please contact us! On our in-house femtosecond laser we can make small samples for demonstration purposes. For stealth-dicing, we can put you in touch with other centres.

This blog post was published in the context of the SURFACESCRIPT COOCK project.