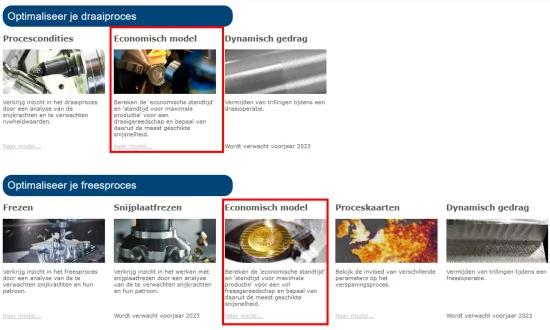

Over the years, various calculation models have been developed that allow machining processes to be analysed and even optimised. These calculation models can be run by anyone on the online platform modelgebaseerdbewerken.be by means of simple forms. In a series of blog posts, we explain how you can use this platform in practice. In this second part, we will discuss how the most cost-effective cutting speed is determined.

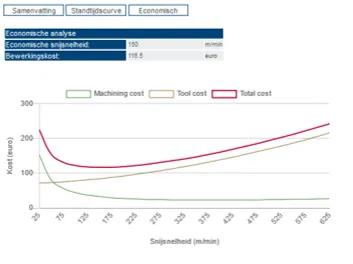

The most economical cutting speed is the one that is the most cost-effective for a certain machine and a given set of cutting parameters. This cutting speed is determined by two important cost items: the machine and the tool. An additional difficulty is that there is a trade-off between them.

Machine cost vs. tool cost

From the point of view of machine costs, you want the highest possible cutting speed, since this maximises the chip load rate, which is the amount of material removed per minute. This, however, puts a high (thermal) load on the tool, drastically reducing its service life and increasing the tool cost. This approach therefore does not guarantee the cheapest machining process.

From a tool standpoint, you want to remove as much material as possible with the same tool over its service life. The service life can be extended by lowering the cutting speed, but this results in a lower chip flow, more machine time and therefore a higher machine cost. So this approach does not guarantee the cheapest process either.

The economic cutting speed

You can enter the data for your own tool and machine into the economic model, which is available on our platform for both turning and milling operations. The model then calculates the curves for both machine and tool costs, which are then combined to plot the curve for effective production costs. The economic cutting speed can then be found at the lowest point of the curve.

Modelgebaseerdbewerken.be

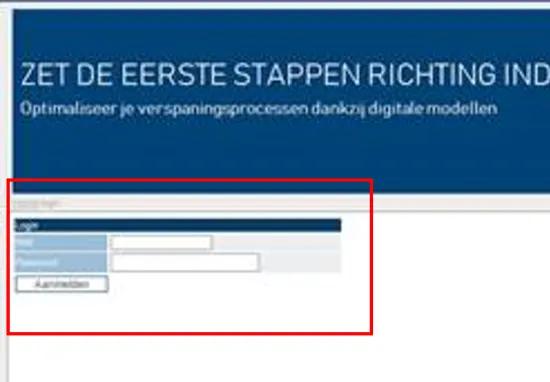

Access to the platform is free of charge, but you do need to register.

- Step 1. Register via the Sirris portal

URL: https://portal.sirris.be/modelgebaseerde-bewerken-login

Important: The code is generated immediately and displayed on the screen. So write it down or copy it immediately.

- Step 2. Go to the online platform

URL: http://www.modelgebaseerdbewerken.be/index.ph

- Step 3. Go to the login screen (top right button)

- Step 4. Log in with your e-mail address and the generated code

You will also find the necessary explanations about working with the models on the platform, but be sure to keep an eye on the Sirris diary because we will be organising both physical and online explanation sessions.

The online platform is part of the COOCK project 'Model-based machining', which was launched with support from Flanders Innovation & Entrepreneurship (VLAIO).