What is the role of surface functionalities and, in particular, the role of textures, in the manufacturing industry in Belgium? That is the question we asked our member companies last summer with a view to rolling out a service on surface textures. The (concise) results are presented in this article.

It is important for Sirris activities to be relevant to its member companies, which is why we regularly survey the market. In this case, we questioned a number of companies both online and face-to-face about the role of surface functionalities, and in particular about how they see structured surfaces for their own company and its applications. The objectives were simple: to find out what technological challenges we need to tackle and what services we can offer to the market.

Useful surface functionalities

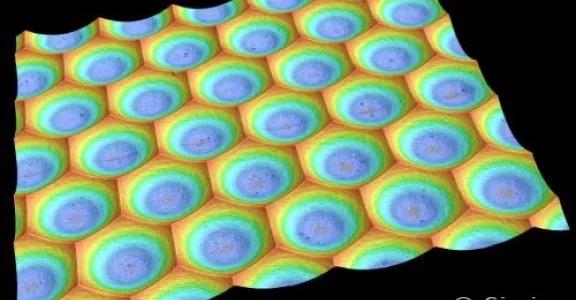

A first question was 'Which surface functionalities are useful for you?’. Respondents had the option to indicate more than one functionality, because this is often the case in practice. This showed that tribology (friction) is by far the most requested functionality. Improving friction between contact surfaces plays an important role in the dynamic behaviour and longevity of machines and vehicles. In many circumstances, such as in the food and pharmaceutical sectors, it is called dry friction, and in that case too, textures offer a great opportunity. In another blog, to be published in the coming weeks, you will get more information about this. In addition, thermal and optical behaviour are also of great importance, thanks to the demand from the lighting and aerospace industry. The other functionalities were more often requested by a few companies with specific applications in mind, but were not generally recurring themes.

Role of surface functionalities

When asked about the role of surface functionalities, 81 percent of respondents said they expect it to be an important issue now and in the future, with increasing needs. 64 percent also indicated that ultra-short pulsed laser texturing is a theme of the future for them and 33 percent indicated that it is not applicable (the rest indicated not to know). It is clear that in some cases textures are not an option and/or do not sufficiently meet the needs, and coatings are clearly the better choice.

Added value

In addition, the extent to which added surface functionality can serve as added value for a company was also examined. 61 percent replied that these surface functionalities make their product more valuable and therefore more competitive, especially if the production process for applying these functionalities has only a limited impact. In some cases the answer was that it does not give a higher sales value, but that it is an essential condition for manufacturing the product.

New initiatives

Another important question is how many companies will actively start projects in relation to this topic. 59 percent said they will launch new initiatives, while 27 percent are waiting for the technology to become more mature.

From this market study it has therefore become clear that surface functionalities are an important theme for the future and that Sirris can play an important role in supporting companies in taking further steps. With our Smart Coatings and Precision Manufacturing (Laser Texturing) department, we have the right competencies to provide sufficient support in this area. Questions? Contact us !