The industry faces quite the challenge: replacing PFAS industrial coatings and their strong functional properties. What if we could replace harmful PFAS coatings with eco-friendly, bio-based solutions? BIOSUPHYOL is making this vision a reality.

Why is it so hard to find eco-friendly substitutes for PFAS?

PFAS coatings: very efficient but toxic and persistent

On one hand, PFAS in general boasts a combination of excellent properties. When it comes to protective coatings, only specific groups of PFAS provide this unique combination of (super-)hydrophobicity and oleophobicity.

- low aqueous surface tension

- water and oil repellent

- non-flammable

- non-sticky and low friction,

- high capacity to dissolve gases

- Very stable and non-reactive

- electro-insulating, anti-static, heat conductive, anti-reflective

On the other hand, PFAS substances are toxic to the environment. Human health and animal life is further impacted by the fact that they degrade very slowly. It’s vital to reduce their use to a minimum as soon as possible. That's why in 2023, the European Chemicals Agency (ECHA) proposed extensive restrictions on the production, use and supply of PFAS.

Textured siloxane: performs well, same toxic issues

PFAS compounds show the lowest surface energy of any chemical compound, which gives it a high combined level of hydrophobicity and oleophobicity. The next best thing is a combination of low surface energy chemicals with microscale roughness or surface texture. This strategy draws inspiration from superhydrophobic surfaces in nature, such as the lotus leaf.

There is a great deal of research in this area, but a perfect and mechanically robust solution is still not available. Achieving the same quality water and oil repellency remains difficult, further hampered by the high cost and the use of potentially toxic materials (nanoparticles, siloxane, etc.).

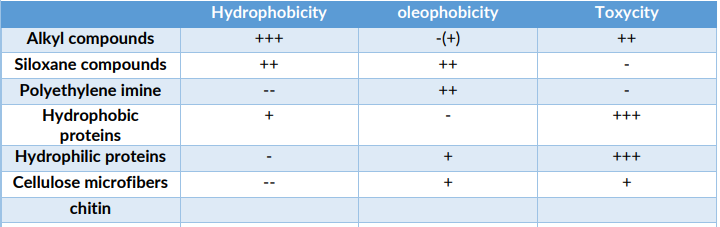

The table below lists the main non-fluorinated compounds used in the literature to achieve water and/or oil resistance. It shows that only siloxane compounds combine these two properties. Like PFAS, siloxane has toxic issues and is also persistent in nature.

Eco-friendly coatings appear on the research horizon

The new BIOSUPHYOL project (BIO-based, SUPerHYdrophobic and OLeophobic) investigates the use of natural and sustainable compounds to develop bio-based protective coatings. Combining mechanical durability and combined functionality, the aim is a product that is 80 to 100% biobased.

- Cellulose microfibres (CMF) are available in aqueous suspension and form good films after spray coating. The water and oil repellency of CMF is enhanced by be surface grafting with non-toxic, non-persistent, low surface energy compounds, such as fatty acids or hydrophobic proteins. The raw materials will be plant-derived, sourced durably from by-products or waste from agri-food, textile, and wood industries.

- To enhance the mechanical stability and lifetime of the coating through internal non-invasive crosslinking. One potential approach is physically crosslinking coating components through charge interactions, which could serve as a first stabilisation mechanism. Additionally, crosslinking mechanisms by UV do not involve hazardous chemicals with limited energy input.

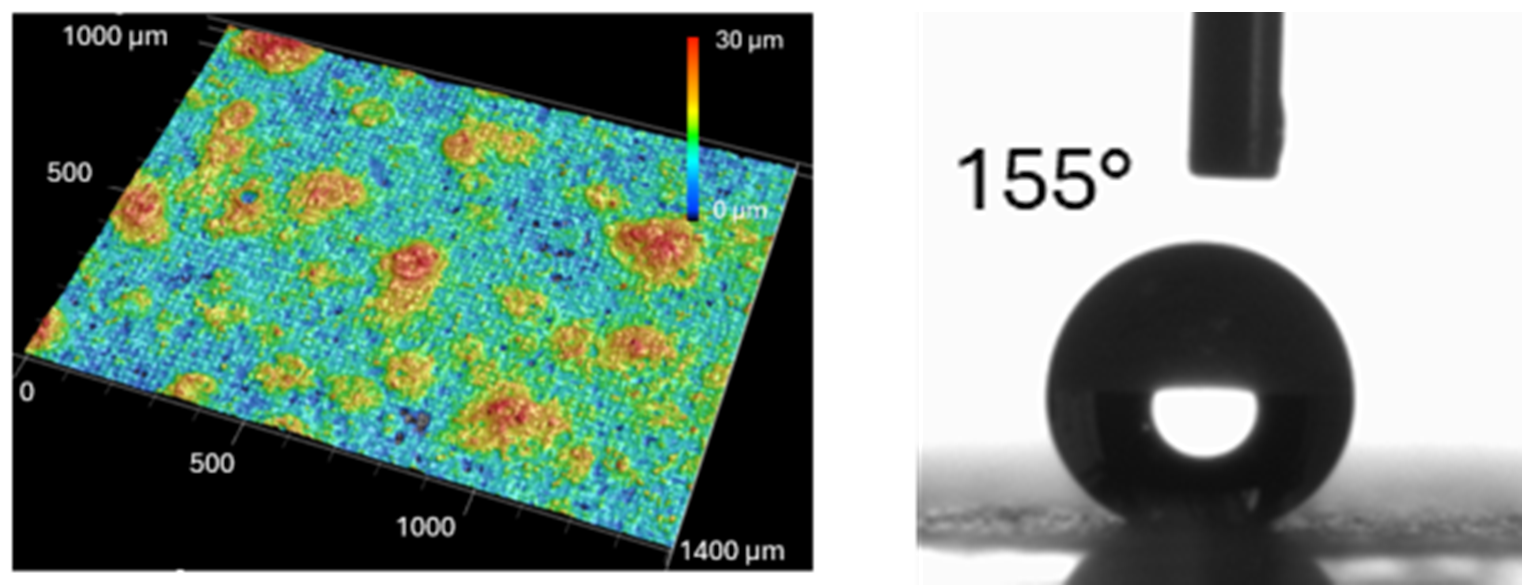

- The additional surface functionalities of the coating will be introduced by laser texturing. This is based on a preliminary feasibility study done earlier within SIRRIS. This showed that texturing can be applied to soft biopolymer coatings by femtosecond laser patterning (see Figure).

Coming soon: sustainable solutions for water and stain resistance

Until now, the development of PFAS alternatives focused on tailored substitutes targeting the needs for a specific application. Currently and historically, the most relevant sector is paper and packaging industries:

- Paper and cardboard production is a significant source of PFAS. It requires alternatives for water and stain resistant packaging (e.g. pizza boxes, paper wrappers for fast food, paper cups, bread packaging, etc.).

- The use of these bio-based alternatives to PFAS in coatings, for example in textiles provides water and oil repellency, stain resistance and flame retardancy (e.g. in protective clothing).

- The developed methodology will be transferred to other industrial sectors by including various substrates (metals, steel, glass, wood) for application in the building and construction industry. This will introduce self-cleaning properties, ageing resistance, anti-corrosion effects, resistance against chemicals and stability against weathering.