BIOSUPHYOL | Biobased, PFAS-free coatings

BIO-based SUPerHYdrophobic and OLeophobic coatings: safe and circular coating alternatives for paper and textile

Creating super-hydrophobic and oleophobic coatings, minus the PFAS-compounds, that is the main scope of the BIOSUPHYOL research project. Among other applications, first the focus will be on paper and textiles, as these are major sources of PFAS release. The coating combines low-energy bio-based compounds with cellulose microfibres to achieve the desired properties. For applications that need to last a long time (e.g. high resistance to abrasion and/or washing), an extra cross-linking step will be added. The resulting materials will be safe and comply with upcoming regulations. Their circular added value lies in the improved recyclability and reuse potential.

Context

Per- and polyfluoroalkyl substances (PFAS) are a class of thousands of substances that possess a few highly specific properties, including the ability to lower among others, high hydrophobicity and oleophobicity, non-flammability, high stability, and low reactivity.

Some of these properties, or combinations of properties, are exclusive to specific groups of PFAS, making them highly suitable for a diverse range of applications, including the electronics industry, textiles, antifoaming agents, paper, packaging, coatings, fire-fighting foams, and more. However, the inherent toxicity of these substances (carcinogenic, etc.) is further amplified by their high stability, resulting in long-term persistence in the environment. It is therefore imperative that we reduce their use to an absolute minimum as a matter of urgency.

Objective and results

This project proposes an investigation into the use of bio-based Cellulose MicroFibres (CMF) surface-grafted with non-toxic/non-persistent low surface energy compounds, with an initial target of 80 to 100% bio-based content. The compounds, which include fatty acids and hydrophobic proteins, are designed for use as mechanically durable coatings with combined functionalities, such as superhydrophobicity and oleophobicity.

These compounds are primarily designed for use in the textile and paper packaging industries. It is expected that these materials and methodologies can also be transferred to other materials, including metals, steel, glass and wood. The modified CMF structures (or combination of them) have the unique potential to combine superhydrophobicity and oleophobicity in the same coating, depending on the material selection and application procedures. This can be achieved by controlling the surface chemistry and surface topography (e.g. roughness or controlled patterning).

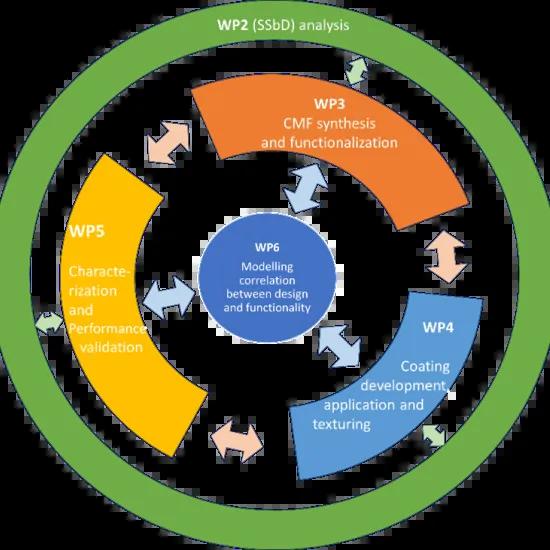

The BIOSUPHYOL project's ultimate goal is to provide a platform of CMF-based materials and protective coating systems that will replace PFAS at TRL 3. Throughout the project, we will implement a Safe & Sustainable by Design-assessment to ensure that the solution does not significantly harm the environment (in line with the European DNSH principle) and is non-toxic in human and environmental exposure.

Approach

Target group

The objective of this project is to develop alternatives to PFAS in protective coatings for the following sectors:

- Paper mills are a major source of PFAS. Alternatives are needed for paper and cardboard packaging with water, fat and oil barrier coatings (e.g. pizza boxes, paper wrappers for fast food, paper cups, bread packaging, etc.).

- The use of these materials in textiles provides water and oil repellency, stain resistance and flame retardancy (e.g. protective clothing).

- The developed methodology will be transferred to other sectors by including various substrates. Once it is made suitable for metals, steel, glass or wood, this technology will become relevant for applications in the building and construction industry. This will introduce self-cleaning properties, ageing resistance, anti-corrosion effects, resistance against chemicals and stability against weathering.

Replacing PFAS in paper-based packaging and textiles is a priority. These products are in direct contact with consumers and PFAS is potentially released into the environment during use and/or at end-of-life.

Funding

Funding agency / agencies

Financed by the — NextGenerationEU

Reference format

Belgium Builds Back Circular / BBBC call 3 / BIOSUPHYOL