Many components suffer a loss of performance due to ice formation. Various technologies are available to 'armour' surfaces against ice or frost formation. In this area, too, micro- and nanostructures made with lasers seem to offer potential.

The formation of ice on parts of air conditioners or aircraft wings, to name just two instances, results in a decrease in performance, in cooling and aerodynamic lift respectively. Numerous applications therefore benefit from preventing or delaying ice formation. In addition to the use of coatings, recent research has revealed potential in the micro- and nanostructuring of surfaces. In addition to being ice-inhibiting, these structures are also more resistant to abrasion.

Such structures can be made with a new kind of laser technology - femtosecond lasers, whose power continues to increase as this technology evolves and matures. The technique makes it possible to structure materials without significant heat damage, which does occur when traditional nanosecond lasers are used.

Function

The process of ice formation is complex. Water droplets can freeze, but frost can also form from just the water vapour in the air. In a recent study, a metal surface was treated with various technologies in order to study ice formation. The figure below shows the growth of frost on polished AISI 430 stainless steel with a roughness of Sa = 40 nm that had been given different surface treatments: 'Plain' (black - polished steel), 'LIPSS' (green - femtolaser-induced nano-wrinkles), 'MS' (red - micro- and nano-structuring by femtolaser), 'LIS' (yellow - silicon oil from Sigma-Aldrich), NeverWet R (blue - Rust-Oleum's state-of-the-art anti-icing coating). Over time, frost will appear on any surface, but its formation is retarded on the treated surfaces, with the micro- and nano-textured surface (MS) performing as well as the commercial coating. Texturing can therefore delay the growth of frost by 10 minutes (<1 hour) before it has the same frost coverage as an untreated surface.

Previous research has shown that the nanostructuring on top of the microstructuring plays an important role. The use of microstructuring only can even give faster frost formation.

Links: A micro- and nanostructured surface (MS) (the yellow bar is 10 µm); right: frost formation (% area) against time on different surfaces. It grows slowest on an MS surface.

Left: a droplet freezing on the various surfaces examined (see text)

What about other forms of ice formation? The sort that comes from rain or liquid water that freezes? Delayed ice formation has also been seen here. It takes longer for a droplet to freeze on a micro- and nano-textured surface. Whereas on a flat steel surface the droplet is frozen after 115 seconds, on an MS-textured surface, it takes 360 seconds - up to three times as long. In addition, MS surfaces could be tuned to achieve superhydrophobicity, so that raindrops can roll off them (beading effect).

Sustainability

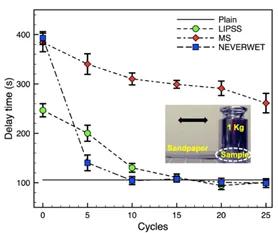

How long will these surfaces last when exposed in an abrasive medium? This has been tested by sanding the surface with abrasive paper. The time required for the droplet to freeze is then measured as a function of the number of sanding movements. It can be seen that the droplets now freeze faster, but compared to Neverwet, for example, the MS surface is more resistant to abrasion. These MS structures are also free of nanoparticles.

In conclusion, we can state that nano- and micro-textured surfaces have potential for ice inhibition. The advantage can be seen in a slower spread of frost or the delayed freezing of the water present. These surfaces also have a definite wear resistance.

Such surfaces can be made with ultrashort pulsed lasers (USL, femtolaser, 10-15 s). At Sirris, we have a femtosecond laser platform for structuring surfaces so that they display new or improved functionality. Do you have any questions about this technology? We’ll be happy to help you! In addition to surface treatments, you can also contact us for icing tests in our climate chamber (link) or for more information about coatings.

This blog post was published as part of the COOCK project SURFACESCRIPT.