Who has not heard of the fantastic benefits that additive manufacturing (AM) technologies have brought to real world applications? We are now seeing parts designed that are lighter, more efficient and that are fancy. Several new technologies in AM have popped up and old ones are getting highly efficient and automated to process materials and generate little waste. There are however, still a few challenges.

Looking to the other side of this technology, which is often referred to as 'the dark side of AM' are the challenges with postprocessing these parts. Take finish machining for example. The real benefits such as light weight and complex geometries become real challenges while machining some features that has to meet tight tolerances. These parts need special work-holding setups and can produce vibrations due to reduced stiffness (due to light weight) that can lead to bad surface quality. The next big challenge is referencing these parts using the datum features, which are still limited to the quality of the surface in as built state.

To understand how these challenges could be tackled, here is a case study.

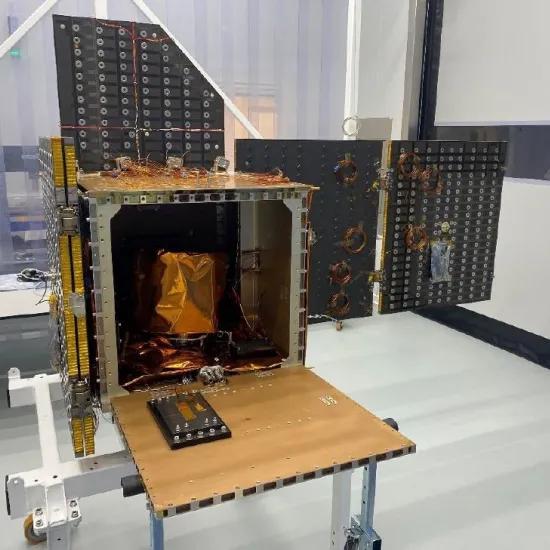

Case study on 3D-printed bracket used in aerospace industry

The part is optimised to reduce the weight of the component and thereby decreasing the buy to fly ratio which is critical in aircraft industry. However, the part has some precise holes which have to be aligned and meet tight tolerance requirements.

1. Effective work-holding

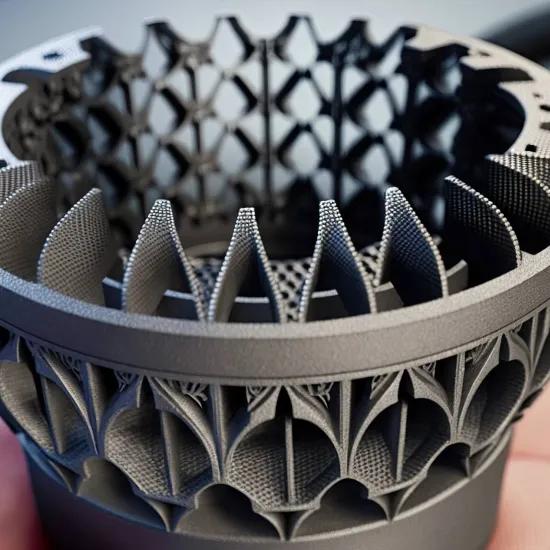

The complex form of the part makes it difficult to grip it securely, in a way that it could reduce the vibrations and part deflections that could arise during machining. These problems could be avoided if we manage to distribute the clamping forces across a larger surface on the part. It is difficult to reach enough surfaces for clamping owing to the organic shape of the part. One way to achieve effective clamping is by using 3D-printed jaws which form the negative of the part surface (see figure below).

2. Referencing the part

The part that is already built is used for generating the final surface features that needs to be machined to meet the tolerance requirements. We need datum features that needs to be sufficiently good to be able to locate the part accurately and align it in a five-axis machine. Probing enough features on the part to accurately locate the part is crucial. Since all the surfaces are already built, care should be taken to have enough stock material to account for the low quality of the as-built surface and part distortions during AM build process.

Precision machining of features on the AM part is usually a process with very high stakes as the part would be scarped if it does not meet the final tolerance requirements. Enough knowledge and expertise is required to be able to successfully machine complex parts built with AM technologies. At Sirris we have put our combined knowledge of additive manufacturing, material know how and years of experience in machining to post finish the AM parts. We run projects with several industrial leaders to make their AM integration more consistent and effective. Experts at Sirris can make the difference that you have been looking for, to help you explore AM technologies and in integrating them in production with its benefits while ensuring high quality products and processes.

Would you like more information about these topics or about integrating AM into your production process? Contact us. Also, be sure to check out our '4.0 Made Real' page to learn more about other related topics.