When two surfaces move across each other, friction occurs. The strength and wear are influenced, among other things, by the roughness of these surfaces. Because of the wide variety of friction conditions and the complexity of the problem, this is a challenging area of research. New technologies, such as femtosecond laser texturing, allow small structures to be introduced into the surface and thus influence the friction behaviour.

Problem

Controlling friction in industrial applications is an opportunity. Just think of energy loss due to friction, a shortened lifespan of components subject to friction or problems creating sufficient grip. Therefore, surface texturing to control friction and wear has been the subject of numerous studies over the past decades. Despite the interest, it remains a challenge to understand the underlying causes of the effects of surface texturing under certain contact and lubrication conditions.

Research at the Department of Mechanical Engineering at Imperial College London, for example, showed that under certain friction conditions, structures vertical to the direction of movement resulted in a reduction in the friction force. The effect of surface textures on friction was investigated experimentally for a convergent-divergent layer operating under different lubrication regimes. Textured patterns, consisting of cavities of varying shapes and orientations, were evaluated for their ability to reduce friction losses. The tests were carried out with a number of lubricants of different viscosity and normal load. The results were compared to those of a smooth reference surface and showed that a friction reduction of up to 62 per cent was possible.

Research into these effects is also being conducted at Sirris. It was recently demonstrated that with a certain texture, the speed of a sleeve bearing can be increased by 20 per cent. Now a broader study is being set up with the support of the steering committee of the SURFACESCRIPT COOCK project.

.

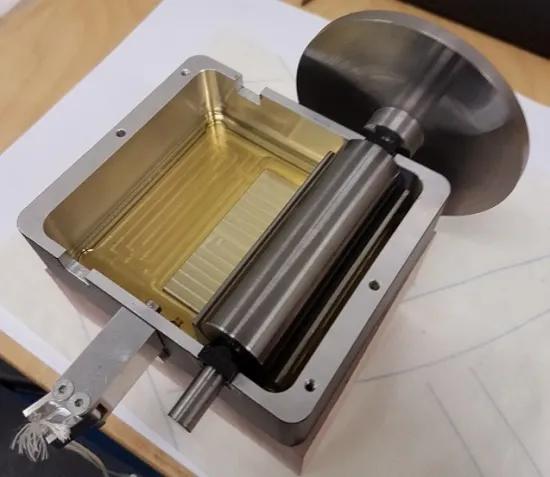

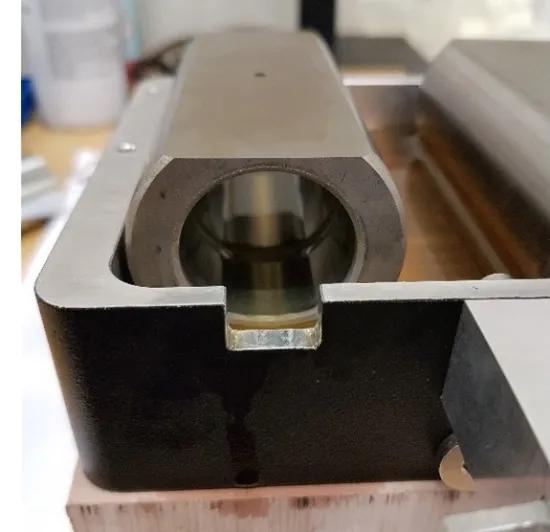

On the left: the sleeve bearing or shaft (with flywheel at the end), on the right: the bushing in the oil bath in which the shaft rotates.

Approach to the study

When optimising a process, there are often several parameters that can be set. How do you go about finding the right settings? What values do you want to try and how many tests can you do? And what about the question ‘how is the result affected if you turn two knobs at the same time?’ The 'design of experiments' (DOE) methodology can help you with this. A good software helps you to set up tests, to evaluate the result and to find an optimal setting. The technique takes variation into account, i.e. the statistical significance of your result.

In the search for a surface modification that can reduce friction, the literature shows that several aspects can be important. What kind of structures are you going to put in the surface? How large and deep will these structures be, and finally, how much of the surface will you be treating in this way? These are the four factors (inputs). The friction force measured is the response (output).

In the following experiment, the texture that gives the lowest friction force is sought. Two to three values are chosen for each factor, in accordance with what is already available in the literature. In this case, the microstructures are chosen in the following way:

- Round holes or long lines (1 mm)

- A width of 20 µm or 80 µm

- A depth of 10 µm or 50 µm

- A surface coverage of these structures of 5, 15, 50 per cent.

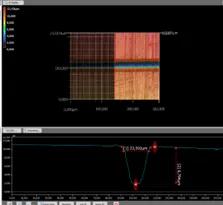

An example of a texture: top view on the left, width (20 µm) and depth (10 µm) of the profile on the right

It is decided to try all conditions ('full factorial'). Such a design allows to understanding the influence of one factor and the interactions between factors. This results in 2*2*2*3 experiments. Three more identical experiments are added to check the reproducibility. In this way, we arrive at 27 axes to be textured and measured.

Setup

The textured shafts are mounted in a bushing that was in an oil bath. Driven by a falling weight (200 g - 1 kg), the shaft will rotate. The speed from standstill to when a constant rotational speed is obtained will be measured by sensors monitoring notches on the rear flywheel.

Optimised demonstrator for measuring textured shafts, where rotation speed is measured via sensors

Once the measurements have been made, the DOE technique allows the influences of the various factors (effects) to be quantified. A mathematical model allows to find the optimal spot or trend within the parameter variations that have been tried.

The results will be published in a later blog.

Do you have a case of your own regarding friction in your company or would you like to know more about our research or activities? Then please contact us!

This blog post was published in the context of the SURFACESCRIPT COOCK project