The new European project NewSkin, in which Sirris is a participant, explores the potential of nano-based surfaces for industrial and consumer products.

The use of Key Enabling Technologies (KETs) will be the driving force for a substantial part of the goods and services that will be marketed over the next decade. Nano-based surfaces take a special place among these technologies, because of their enormous potential to provide material solutions for Sustainable Development Goals (SDGs). These solutions will result in a positive impact on society and key industrial sectors.

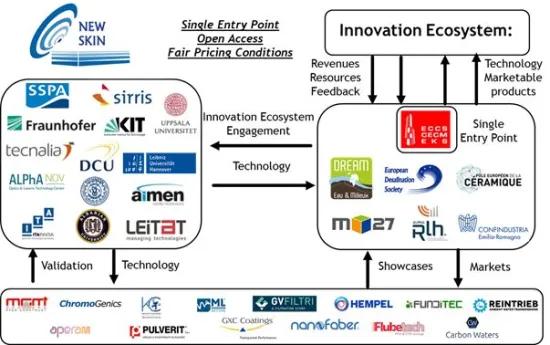

NewSkin aims to accelerate the industrial adoption of surface nanotechnologies in Europe. The objectives of this H2020 project include creating an ‘Open Innovation Test Bed’ (OITB), a new legal entity that will provide the European Innovation Ecosystem with the necessary technologies, resources and services to include a set of ground-breaking, efficient and cost-effective innovative processes for the production of nano-based industrial and consumer products, as well as the necessary testing capacity to demonstrate the properties of nano-based goods.

The innovative production facilities for upscaling and testing will provide the Innovation Ecosystem with the necessary tools to create TRL7 and new technologies to meet the challenges of key European sectors such as steel, ceramics, transport, water treatment and industry in general.

Set-up for icing research

Icing test setup being built in the Sirris climate chamber

Sirris participates in this project with the OWI-Lab and Smart Coating Lab. A test set-up for icing is being developed for this purpose in the large climatic test chamber of Sirris. The dimensions of this set-up will be approx. 6 m x 3 m x 5 m and ice accretion will be formed by atomisation. Different ice structures and types will be created with the greatest care. Due to the size of the set-up it will be possible to test the effects of icing simultaneously on different coating samples. In addition, the set-up will make it possible to test the functionality of the coatings applied to the real large components. To be measured: the time needed to form and melt ice, the thickness, colour and adhesion of the ice and drop formation. 3D scanning and a thermal camera will be used to examine the ice’s shapes and other properties in more detail.

Sirris will immediately translate the knowledge gathered during the project to the Flemish industry via the COOCK project 'Fighting Icing', in which concrete solutions for icing problems and their implementation are investigated.

Interaction between OITB partners and Innovation Ecosystem

Click here for more information on the project Newskin.