Today, due to technological advances in the medical world, prosthetics include the ability to replace a diseased or damaged knee or hip joint. Yet sometimes inflammation or infection already develops after implantation. This brings a lot of suffering to the patient. This is because the prosthesis has to be removed, the patient has to recover and, finally, one can proceed with another operation. So preventing this infection is literally solving a pain point.

Structures tailored to germinate

Such an infection can include a bacterium that has ended up on the prosthesis. Therefore, the possibility of making prostheses bacteria-resistant is being investigated. Femtosecond laser technology allows making structures of the order of magnitude of these microorganisms. Research has shown that relevant bacteria (such as the staphylococcus aureus bacteria common in humans) have a harder time thriving on it.

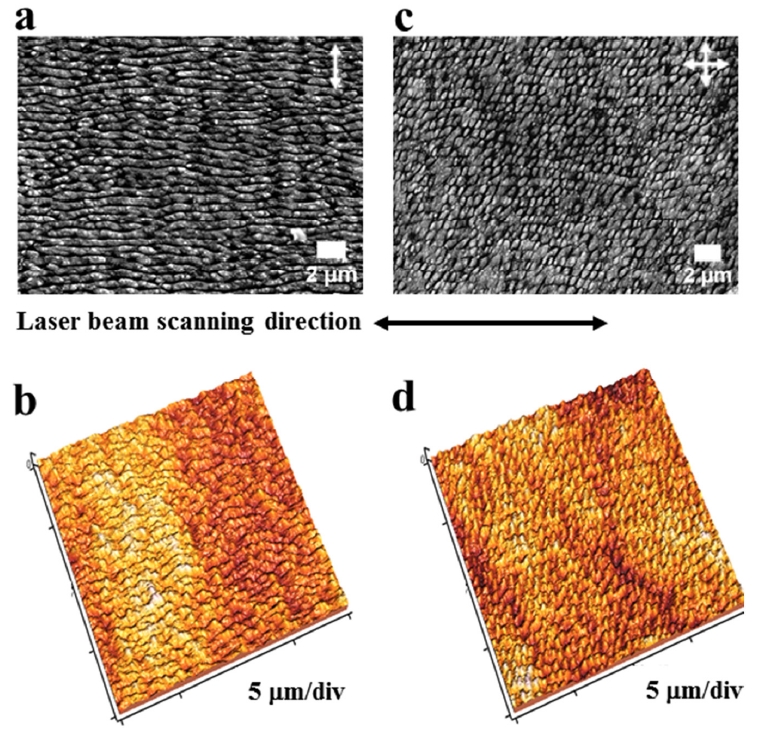

The figure below shows on the left the structures, so-called 'LIPSS', that were applied to titanium grade 2. On the right-hand side, the top two figures (a,b) show bacterial growth on an untreated surface, the four figures below show bacterial growth on a textured surface: (c,d) LIPSS and (e,f) nanopillars. Growth was inhibited (~factor2) on textured surfaces.

|

|

|

In addition to preventing bacterial infections, the bone must grow on the prosthesis properly so that it does not become loose. This does not work well on polished titanium. Therefore, this material is roughened by sandblasting it in the areas where the prosthesis is to adhere. Applying structures in combination with femtosecond laser technology can further improve cell growth, as shown in the study below (graph). Four situations were compared here: polished titanium (pTi), sandblasted Ti (STi), Femto-textured Ti (FTi), sandblasted and femto-textured surface (FSTi). Connective tissue (collagen, Y-axis) grows the fastest on the FSTi surfaces, as measured by optical density (OD). Both examples cite the potential of USL for improved prosthetic uptake in the body, (see also the study's website).

A femtosecond laser platform is available at Sirris, on which you can have feasibility studies and research carried out according to your material or application. With USL technology, we functionalise surfaces including water-repellent, ultra-black, and friction-reducing. Other properties are also possible. Do you have questions about surface functionalities and the possibilities with ultra-short pulsed lasers? Then please contact us!

This blog post was published as part of the COOCK-project SURFACESCRIPT.