How can an anti-icing coating help combat icing problems? How can it be implemented and how can its effect be simulated in a lab? These are the questions behind the launch of the COOCK project Fighting Icing and the NewSkin programme.

Since the start of these initiatives, Sirris experts have taken up the challenge of developing a test methodology to achieve homogeneous icing under controlled conditions. To this end, a mobile spraying system was fitted into the existing large climate chamber, allowing a total area of 25 m² to be uniformly coated with ice using 25 spray nozzles.

The set-up allows to assess new ice detection systems and anti-icing solutions (coatings and structured solutions) in collaboration with various companies active in wind energy, aerospace, construction, etc.

Anti-ice coatings

Anti-icing coatings are formulated to repel ice and water droplets, prevent the formation of ice cores on surfaces or reduce ice adhesion.

In an ideal scenario, icing is delayed or the ice is removed purely by the force of its own weight or by the effect of wind. However, these coatings are often used in combination with active electro-thermal or pneumatic systems.

The different types of anti-ice coatings were discussed in a previous article.

For companies, it is crucial to evaluate the performance of these coatings under realistic conditions, as well as the durability of these systems, with respect to specific applications.

Results of benchmark tests

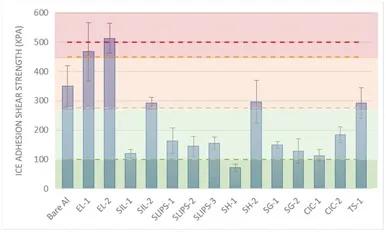

The benchmark tests on different coating technologies, for which suppliers from around the world were contacted, were recently completed. In these tests, the behaviour of different types of anti-ice coatings was studied in detail and the results show remarkable differences between the coating technologies, on the one hand, and the results within the groups, on the other, depending on their mechanical loading and UV exposure.

This clearly demonstrates the importance of conducting the tests in a controlled environment and in conditions representative of the application in which the coatings will be used.

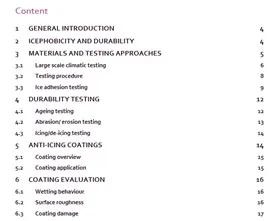

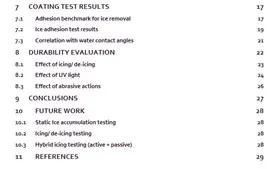

Below you can have a glance at the contents of the report explaining the full results of the benchmark coating study and our ice testing methodology. Interested? Contact our experts.

From concept to implementation

The direct applicability of anti-ice coatings is often restricted due to their limited durability in harsh winter conditions. Therefore, they are often considered only as temporary measures. However, in combination with active anti-icing or de-icing systems, they can provide significant benefits, such as a reduce energy consumption, by reducing the need to switch on the systems due to ice prevention or by facilitating ice removal.

Sirris's setup allows the coatings to be exposed to a series of consecutive ice cycles to simulate different ice days in a winter period. Sirris also combines these tests with abrasion tests, as a simulation of erosion and UV tests, to simulate exposure to sunlight. In this way, the durability of the coatings is optimally evaluated, and decisions can be made towards the applicability of the coating, full cost estimate, need for inspection techniques, idea of reapplication and planning of maintenance works. Grading all coating aspects in application, shown in the figure below, would reveal the strengths and weaknesses of the coatings. Such information can be very useful to coating developers to improve their coating systems and for asset owners to select the best coating for the job.

Previous publications and articles

Available as a download version:

Three white papers on ice formation

- Icing and its impacts

- Ice detection: State of the art methods & techniques

- Anti-ice coatings: Overview of technologies

'Unique set-up for performance analysis of drones in wind and icing conditions', Ozlem Ceyhan Yilmaz, Daniele Brandolisio, February 2022 (see: 'Unique testing set-up for performance analysis of drones in wind and icing conditions').

Available on request:

- Icing Challenges and Testing Methods for Electrical Power Lines and Switch Gear Components

- Durability of anti-ice coatings