Gaining a competitive advantage through additive manufacturing all depends on your ability to optimise lead times, reliability, product quality and costs. That, in turn, is related to how you leverage your digital process data and how you integrate additive manufacturing with other technologies, including machines and digital tools. Indeed, there are a lot of dots to connect, but Sirris is here to help. From choosing the right equipment for your needs to measuring, adapting and predicting your additive manufacturing processes, we’ve got your back.

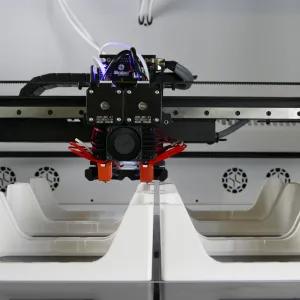

Integrating additive manufacturing on the shopfloor

Your go-to option for customisation and complex shapes

From reduced costs for prototyping to limited on-hand inventories, additive manufacturing comes with many benefits. However, the true value is in the products themselves, as the technology is ideal for functional products that require:

- a high degree of customization

- complex shapes that cannot be obtained with traditional machining technologies

- components with a large surface (e.g. lattice structures)

- a light weight

- new materials (e.g. advanced polymers and electro-magnetic metals)

- multi-material applications

For all companies with a taste for additive manufacturing

No matter what (niche) market you’re in, we help you to get the most out of additive manufacturing. A selection of the issues we’re happy to tackle for you:

- How to filter, structure and integrate digital process data (formats, algorithms, etc.)

- What to look for in a Manufacturing Execution System (MES)

- How to trace an additive manufacturing product with an e-ID

- How to digitally support your additive manufacturing operators

- Which new materials could serve your additive manufacturing goals

- What additive manufacturing means for your product flows, planning, quality assurance, etc.

Inspiring articles

Upcoming events

Let’s integrate additive manufacturing on your shopfloor!

Olivier Rigo , our Program Manager Additive Manufacturing, will guide you through the options.

Get in touch