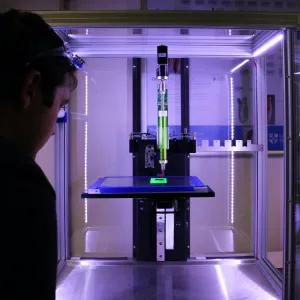

To produce high-quality products with additive manufacturing, you need to master everything from raw materials and design to additive processes, parts cleaning and finishing. Our additive manufacturing laboratories help you identify the right variables to control, leverage relevant data insights, and set up an integrated process to guarantee quality.

Quality assurance for additive manufacturing

Quality and reliability challenges in additive manufacturing

In additive manufacturing, getting in-process feedback on part quality is hard, even for skilled practitioners. Furthermore, the machines and processes are inherently variable, the build process includes many adjustable inputs that can affect quality, and the industry itself has few design rules or quality standards. As a result, companies struggle to assure quality and reliability. That’s why we provide expertise in every stage of the value chain.

Need a quality boost?

Are you facing unexplained quality problems in your additive manufacturing? Do you want to improve quality or process conditions of your additive manufacturing machine with data? Can’t decide in which process or material monitoring techniques to invest?

You have questions. We have answers. At Sirris, we analyse your problems, identify root causes, monitor key parameters, measure impact, and more, across the entire design and production chain.

Mastering abilities and limitations

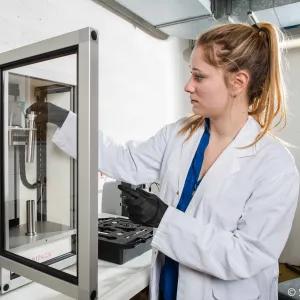

At Sirris, we have over 30 years of experience with design, process optimisation, quality control and digitalisation. As a result, our experts master the whole design and production process chain: from raw material to printed product and post-processing for a wide range of additive technologies and materials.

Thanks to our multi-disciplinary team of experts, you’ll:

- identify the root cause of quality issues quicker, whether it’s design, feedstock, process condition or heat treatment;

- improve the transparency of your additive manufacturing process with data;

- identify the relevant standards to follow;

- learn about well-fitted manufacturing conditions for your product or materials;

- get access to process simulation software that will help you better understand and improve the thermal conditions of your process;

- be able to adjust your heat treatments and evaluate their efficiency on internal stresses;

- get advice on how to process your data from your in-situ monitoring systems;

- have your own database for training AI models that can help improve quality.

Additionally, the majority of the Sirris’ additive manufacturing equipment includes in-situ monitoring systems.

Inspiring articles

Add confidence to your additive manufacturing process.

Our expert Thomas Kairet will help you on your way.