MW4REMAM | Microwave enhanced recovery of REEs and plastic from WEEE and re-use in AM of novel magnetic components

The goal of this European project is to use innovative microwave technology to improve the recovery of rare-earth elements (REEs) and plastics from end-of-life electric and electronic devices (WEEE). The waste will be recycled as raw material to create magnetic components, by using additive manufacturing.

Rare earth elements (REE) are essential materials in connected and electrical technologies due to their unique properties, making them suitable for use in various high-tech applications. They are currently the subject of great interest regarding the transition to decarbonisation and a greener economy.

The main objective of the MW4REMAM project is to develop an innovative technology for efficient recovery of both rare earth metals and plastics from waste of electrical and electronic equipment (WEEE), to produce plastic-REE composite filaments and create new magnetic components via additive manufacturing.

The specific objectives of the project are:

The development of a microwave technology for the separation and recovery of plastic and REE from discarded NdFeB magnets in WEEE with high efficiency and low environmental impact.

- The production of nano and microcrystalline REE powders by means of mechanochemical processing

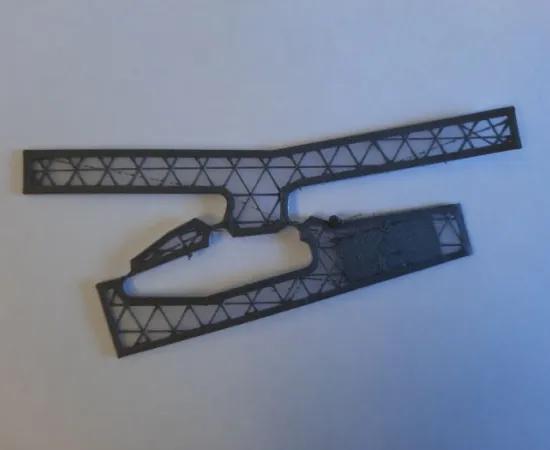

- The production of plastic-REE composite filaments from prior recycled materials and the demonstration that composite materials can be re-used through additive manufacturing of new magnetic components via fused filament fabrication (FFF) technology

- The estimation of the environmental impact of the new technologies in order to meet the European Green Deal targets

- To raise awareness among the general public about the environmental and economic benefits of recycling REE from WEEE and the innovative potential of re-use in additive manufacturing of magnets.

The proposed project is highly innovative at European level because of its development in the field of REE and plastic recovery by microwave technology. It is an important step forward in the economic and ecological processing of small NdFeB magnets from WEEE, as both plastics and REE materials can be reused in additive manufacturing to produce (redesigned) new magnetic parts.

| FADDTORY SPRL | Belgium |

| Development and production with fused deposition technology. LCA and LCC analyses | |

| Institute of Catalysis – Bulgarian Academy of Sciences (IC-BAS) | Bulgaria |

| Mechanochemical synthesis of micro/nano powders | |

| SIRRIS | Belgium |

| Compounding, development and production with fused deposition technology | |

| Daily Sources and Research SRL | Romania |

| Technology in microwave processing of WEE | |

| National R&D Institute for Nonferrous and Rare Metals (IMNR) | Romania |

| Technology in microwave processing of WEEE | |

| Travelec SA | Belgium |

| Test and evaluation of properties of the FFF shaped materials | |

Funding

- Programme: ERAMIN

- Funding agence: Région Walonne