Application of and research into the reduction of friction and associated wear through small structures has been around for a long time. We provide a successful example of how the direction of the texture can provide the greatest friction reduction.

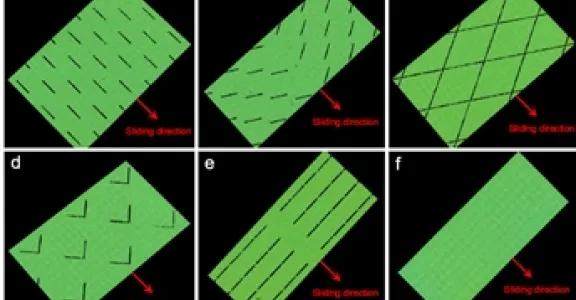

Reducing friction and wear by applying small structures to moving parts has a long history. Its first application dates back to the 1940s in the piston-ring-liner system of diesel engines used to prevent seizure at high temperatures. Much research has been done since then, up to the present day. Sometimes successful and sometimes not. Clear, generally applicable guidelines for the creation of textures are still under discussion. All the more so because the variation in application, conditions and parameters is great. Consider, for example, differences in the type of contact (conformal vs. non-conformal), regime (dry, boundary layer friction, mixed friction, hydrodynamic friction), etc. Nevertheless, there are positive results and in this blog we show one of them.Research into the direction of texture has shown that in the case of boundary layer friction, the greatest reduction in friction is obtained if the longitudinal direction of the structures is vertical to the movement. This is in contrast to similar structures that lie along the length of the movement, where greater friction is observed.

Reduced friction not only has an impact on service life, but primarily on the power required (see figure below). The influence of the textures is particularly pronounced as the friction components are pressed harder against each other.

It’s important to note that this doesn’t apply to all the friction regimes studied in this study. If the components are not pressed hard against each other, a thicker oil layer is present (hydrodynamic case) and it is better not to introduce any structures.