Recent research and testing have shown that bio-based coating formulations can outperform traditional fossil-based polymer coatings. As such, the coating lifetime can be extended or the coating can eventually perform better under high-loading conditions. The availability of thermo-analytical testing facilities at Sirris’s testlabs assists in optimizing coating compositions and processing conditions.

Introduction

Today, several grades of bio-based polymer coatings are introduced in the market.. Instead of traditional fossil-based resources, plant-based or vegetable oils, or lignocellulosic feedstock serve as the building blocks for new coating resins. In parallel with a slightly higher price of bio-based products, often equal composition and properties compared to the fossil-based coating are claimed. However, recent studies have illustrated that the bio-based coatings may additionally have an improved performance in terms of mechanical properties or abrasion resistance. In particular, intensive testing reveals that a given range of operational conditions can be selected where bio-based coating formulations outperform the traditional fossil-based polymer coatings. As such, the coating lifetime can be extended or they can eventually perform better under high-loading conditions.

Needs for testing

The optimization of bio-based coating formulations requires good understanding of their intrinsic properties through experimental testing. Although knowledge on the full chemical analysis of their composition is often not needed, the thermo-analytical properties provide insight in their molecular structure and resulting macroscale performance. The mechanical and micromechanical properties of polymer coatings are highly influenced by temperature and deformation rates. At the microscale, the mobility of the polymer chains are an important factor to understand, as it modifies the bulk mechanical properties such as elasticity modulus and yield strength. The occurrence of temperature gradients and/or effects of local frictional heating may also cause local changes in molecular mobility and introduce a transition from brittle into ductile fracture. For amorphous polymers, the glass transition temperature provides good information on the internal molecular structure as the polymer behaves as hard and brittle at lower temperatures and it becomes soft and more ductile at elevated temperatures. For semi-crystalline polymers, the melting trajectory provides information on the molecular structure and molecular weight distribution while it also determines the upper limit of use.

The thermal analysis techniques (DSC, DMA) are excellent tools to detect the intrinsic properties and quality of polymers. The thermo-analytical characteristics may help to understand their performance and/or detect anomalies in their structure. The techniques are frequently used in quality control and failure analysis of polymers. At Sirris, the techniques are available and used in a cooperation between different departments, in order to assist material characterization and support companies in material development .

Formulation and mechanical testing of biopolymer coatings

Within the BioCoat project, comparative studies have been performed on the processing conditions and abrasion resistance of fossil- versus bio-based polymer coatings. These studies help to identify optimum operational conditions for mixing (while mastering the often higher viscosity of bio-based monomers) or indicate distinct behaviour in wear properties between several polymer coating grades. In particular, various grades of bio-acrylate coatings and bio-epoxy coatings were selected and tested as protection for wooden floorings.

The abrasive testing revealed distinct properties with higher loading capacity and better abrasion resistance of bio-based coating grades under specific testing conditions. The reason for that can be seen through close observation of the wear track, where a protective layer is formed through deformation of the coating layer. In contrast, the wear track for fossil-based coatings was smoother and characterized by brittle cracks followed by material removal. The similar observations were concluded from scratch resistance testing, with either a brittle or more ductile scratch depending on the coating grade (see Figure 1).

Although identical chemical composition of the bio-based and fossil-based polymer coatings is claimed, variations in molecular microstructure remained unclear, which could be a reason for the distinct behaviour.

Figure 1. Mechanical performance of fossil-based coatings with brittle behaviour and bio-based coatings with ductile behaviour

DMA (Dynamic Mechanical Analysis)

The evolution of mechanical properties, particularly stiffness and visco-elastic properties, can be recorded as a function of temperature through DMA analysis. A small material specimen is cyclically loaded at given frequency and the deformation response is measured in two components: one in-phase component characteristic for the elastic response and one out-of-phase component characteristic for the visco-elastic (time-dependent or delayed) response. The response of the material is studied according to the so-called time-temperature superposition, where the testing of a material under the high deformation rates is equivalent to the testing under the low temperatures, or the other way round.

As a result from comparative testing of bio-based and fossil-based coatings, the elastic modulus (E’), viscous modulus (E”) and mechanical dampening factor (tan delta) are represented as a function of temperature in Figure 2. The plot evidently indicates the progressive softening of the polymer coatings at increasing temperatures. In particular, the bio-based coatings have lower elastic modulus (E’) and are thus softer. Indeed, the latter properties may improve the lubricity of the coating, as observed during the wear testing. More interestingly, the viscous modulus (E”) for bio-based coatings is higher than for fossil-based coatings, which is also represented by the higher value of the dampening factor (tan delta), particularly in the operational window 0 to 35 °C. The data on mechanical dampening provides unique information as it is a measure for the uptake of mechanical energy. Indeed the higher dampening for bio-based coatings is in parallel with the more ductile properties observed during wear testing. The higher dampening factor intrinsically relates to a molecular structure with more rotational freedom of the polymer chain segments, where the structure of bio-based polymers might be characterised by a fraction of molecules with smaller molecular weight. This fraction indeed provides benefits for improved lubricity during mechanical testing.

Figure 2. Result of DMA testing for bio-based and fossil-based polymer coatings: bio-based coating 1 Hz (black), bio-based coating 10 Hz (red), fossil-based coating 1 Hz (blue), fossil-based coating 10 Hz (green)

DSC (Differential Scanning Calorimetry)

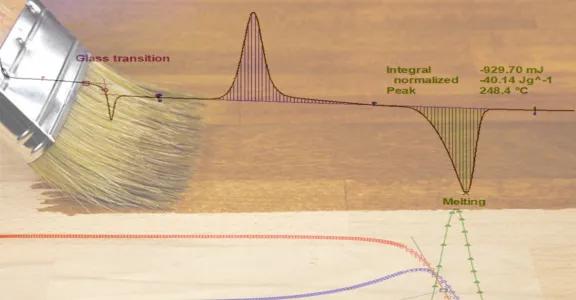

The primary and secondary thermal transitions during heating of a polymer sample are detected by DSC analysis, measuring the variations in heat-flow towards a polymer sample relatively to a reference sample. In particular, the glass transition temperature of amorphous polymers is determined as a characteristic feature, where the polymer changes from a hard and brittle into a softer and more rubbery material. This behaviour is related to the relaxation of molecular fragments and thus reveals information on the molecular structure and organization of the polymer chains.

A comparative DSC analysis between bio-based and fossil-based acrylate coatings in illustrated in Figure 3, showing the heat flow curves during the second heating cycle between -80 to 200 °C with variations in glass transition temperatures. The glass transition temperature obviously increases for polymers with a higher cross-linking density, as the molecular mobility for the highly cross-linked polymer networks is reduced. It can be seen that the glass transition temperature of the bio-based coatings is a few degrees lower compared to the value of the fossil-based coatings, which indicates higher molecular mobility of the bio-based coatings. This behaviour is indeed in relation with the better abrasive properties of the bio-based coatings, as those materials are less brittle. The few degrees difference in glass transition temperature can be likely related to the presence of a polymer fraction in bio-based coatings with low molecular weight, enabling the lubricating properties. By comparing different methods for thermal analysis, both DMA and DSC techniques are very complementary and have different sensitivity to detect the thermal transitions.

Figure 3. Result of DSC testing for bio-based and fossil-based polymer coatings: bio-based coating with low cross-linking (green), fossil-based coating with low cross-linking (blue), bio-based coating with high cross-linking (red), fossil-based coating with high cross-linking (purple)

Access to thermo-analytical testing labs

Sirris provides thermo-analytical services (DSC, Flash-DSC, TMA and DMA) for our customers for a wide range of materials.

Please visit available analysis techniques within Sirris’s Testlabs at https://testlabs.sirris.be/test/#plastics for more information or contact us!