Nowadays, it is difficult to find an AM machine, making metal parts at a relatively low cost, making the technology inaccessible for many smaller companies. On 14 December, the FabricAr3v project partners will organise a conference & networking day on low-cost metal 3D printing technologies.

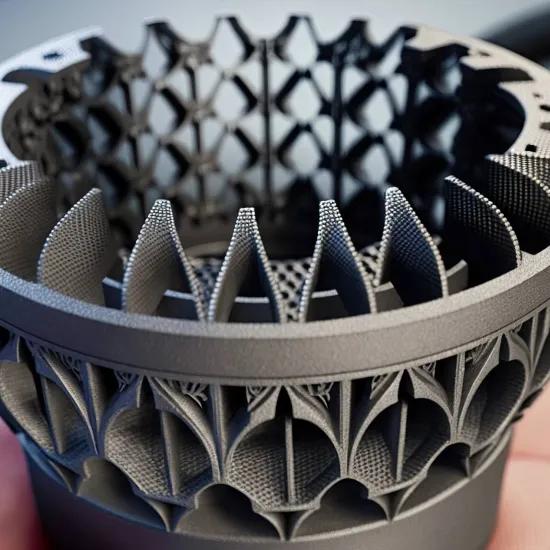

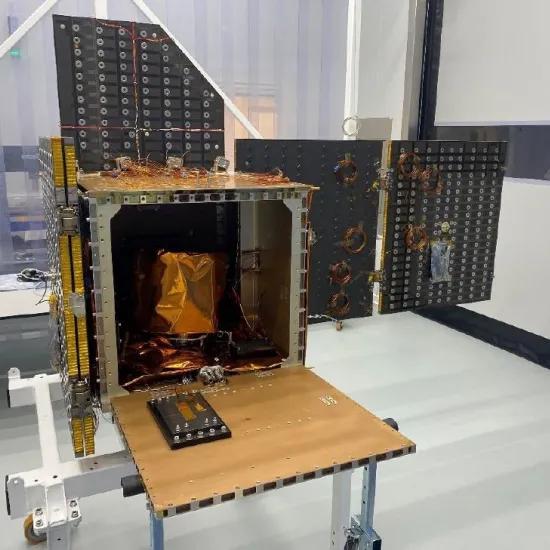

Metal additive manufacturing is a very fast growing sector. Today's technologies require a great deal of expertise and significant investments, hindering the adoption of this process. More affordable processes are therefore required. New technologies, based on MIM (metal injection moulding) technology, pave the way for the advent of much cheaper machines. The objective of the Interreg project FabricAr3v is to develop a process with an overall investment of less than €30k, making it accessible to very small businesses and FabLabs. To switch from rapid prototyping to additive manufacturing, it is necessary to be able to predict defects in parts and control the process in order to predict the mechanical performance of the parts produced. The Interreg project responds to this problem by designing a 'low-cost' process and developing and validating dedicated simulation tools. The skills to be implemented are varied, making the formation of a cross-border consortium absolutely necessary.

All-day event

Within the frame of this project an event on the topic of low-cost metal 3D printing technologies will be organised. On the programme are a presentation of the project and the Interreg programme France-Wallonia-Flanders, followed by four round tables with different topics:

The first round table on metal printing technologies ('Technologies d’impressions métalliques') will be in cooperation with Sirris: we will bring a presentation on the state of the art in industrial additive technologies for metals.

The other round tables will be on indirect metal printing technologies ('Technologies d’impressions métalliques indirectes'), numerical additive manufacturing methods ('Méthodes mumériques pour la fabrication additive') and sociology of 3D printing ('Sociologie de l’impression 3D: alternatives et perspectives pour la FAM').