Prior to their introduction to the market, bio-based products are extensively tested. In this respect, there is a growing interest in sustainability tests, especially for demanding applications, in new test methods and in the right test methods. Let’s have a look at today and tomorrow.

Bio-based shopping bags in Ikea, Lego blocks made from bioplastics, Coca-Cola bottles made from recycled PET (polyethylene terephthalate) and wall panels made from biocomposite material are just a few examples of bio-based products that will be completely normal within a few years. Prior to their introduction, these products have of course been extensively tested.

The aim is to have the highest possible bio-content, while the renewable source used must be demonstrated, but of course these new products must offer a sustainable solution with properties that match those of traditional fossil-based products.

A new product design or new product composition is always based on performance indicators such as product performance, technological feasibility and environmental impact. These can usually be determined in advance. However, determining the potential and possibility for further optimisation depends on product testing, pilot testing and sustainability testing.

Important to determine the potential of new developments is the rapid production of a demonstrator, the performance of tests in a simulated environment and a controlled user evaluation.

Bicycle bridge made of biocomposite

A good example of the possibilities with extensive testing is the realisation of a biocomposite bicycle bridge in the Netherlands. In 2017, the first plans were made to replace a 66 m long bicycle bridge with a bridge made of biocomposite material. The composite would consist of balsa wood, flax, resin and a hardener. In cooperation with educational institutions, a materials study was conducted to arrive at an optimal composition of the biocomposite. Prior to the construction of the bridge, a replica was made on a scale of 1:3 by TU Delft. This replica was used to test the mechanical resistance of the bridge element by simulating the opening and closing of the bridge.

The positive results of the simulation tests and cooperation with architects ensured that the bridge was built and put into operation at the end of 2019.

Importance of durability testing

The development of bio-based products focuses primarily on the properties achieved immediately after production.

However, less data is available on the long-term effects on these properties. Especially when they are used in demanding applications, it is important to be able to map out the effects properly. Because you do not want to wait too long with the market introduction, accelerated life cycle tests are very important.

A recently published article provides a nice overview of the most commonly applied durability tests on biocomposites. The differences in results of the described tests emphasise the complexity of biocomposites and the importance of testing. Here, the interactions and bonding mechanisms between the different components are crucial to ensure good durability. A correct selection of components, in combination with a surface treatment or the use of a coating, can significantly improve the durability of biocomposites. Improvement processes in combination with durability studies should allow new biocomposites to be used in high performance applications.

Need for renewed tests

New prefabricated products based on wood and other bio-based materials, such as plant-based insulation, can also have a positive effect if used alongside traditional wooden structural elements. The insulating material can act as a buffer store for water. New test methods are needed to verify such effects of different insulating materials such as flax, hemp, wool....

Researchers at Bangor University (Wales) therefore created an experimental set-up to simulate the degree of moisture transport and mould growth on wood. They did this by using agar plates covered with the insulation material and shielded from the wood. The test showed that with some insulation products, it was possible to keep water away from the wood and thus prevent mould growth, while other materials could prevent the growth of mould through the materials.

Importance of correct testing methods

New bio-based composite building materials, composed of natural fibres, clay, loam, waste from the cement industry, etc., can be pressed into blocks. These can be used as structural elements in indoor and outdoor applications, and can be provided with an additional finish.

In the assessment of their properties, the focus is usually on testing for water penetration and shrinkage. Various procedures can be used to test the water resistance of the produced blocks: immersion test, capillary absorption test, contact test, dry-wet test, freeze-thaw test, spray erosion test and water absorption test under low pressure. Which test is relevant is mainly determined by the intended application of the composite blocks and whether they are used in a final application, either treated or untreated.

It is important, with a view to specific applications, to make the right choices for testing and also to try to determine the potential long-term effects. Furthermore, in improvement processes, it is important to check the effects of the individual components on other properties such as insulating capacity, sound absorption, chemical and mechanical resistance.

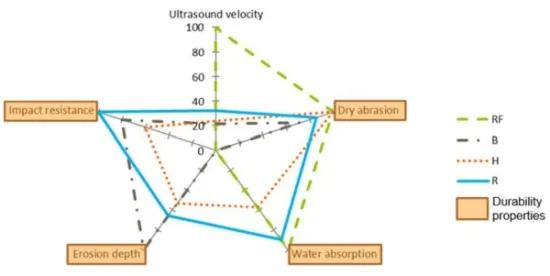

Comparison between biocomposites: Rf = reference material, B = straw addition, H = hemp addition, R= rice husk addition

(Source: https://www.lidsen.com/journals/rpm/rpm-03-02-016)

Validation and verification

During the development of a bio-based product, it is important to find the balance between having the highest possible bio-content, without having to compromise on product properties and price. Obviously, the verification of the bio-based content of products is important for customers, suppliers, producers and distributors or even in the development phase. Determining the correct content is also important for certification or eco-labelling purposes. This also applies to products manufactured from a recyclate stream, biodegradable products or biocompostable products.

Nevertheless, the bio-content is not the only way to demonstrate that a product is produced sustainably. Life-cycle analysis, energy efficiency and end-of-life requirements are some other examples that may give a better insight into the total environmental impact of a product.

Nature-based offices

With the support of the Province of Flemish Brabant, a cooperation project was recently set up with four material manufacturers who will incorporate natural fibres into their materials. They are:

- Circular matters: biocomposites (https://www.circularmatters.com/)

- Orineo, Touch of nature: cast floors and fibre boards (https://touchofnature.eu/)

- BC materials: natural plaster (https://www.bcmaterials.org/nl_2_home.html)

- Fairm (formerly Fungalogic): mycelial material (https://www.fairm.nl/)

These materials will be used to design seven new (finishes of) office furniture pieces. Through these pieces, the possibilities of the materials can be shown to the general public.

Sirris will be involved in testing these bio-based materials, focusing on mechanical strength, moisture absorption, stain resistance, as well as wear and tear, rigidity and durability.

Would you like to know more about possible tests or the use of (biobased) coatings? Please contact us, visit our website or take a look at the annual report!

]]>