In our factory with 4.0 technology, we aim to 3D print a watch. We use a femtosecond laser to create an optical effect, and we couldn’t be more impressed!

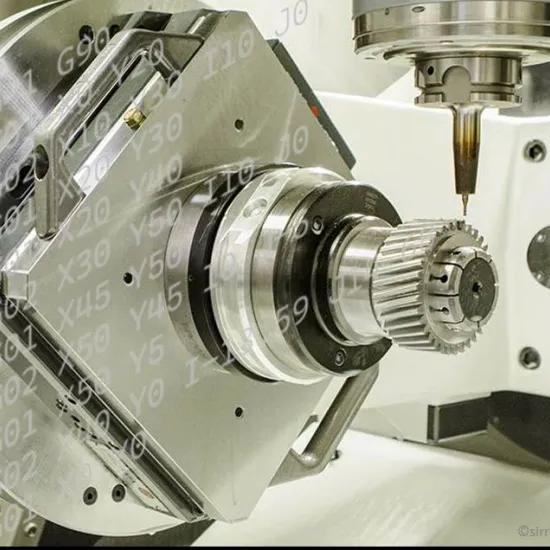

Femtosecond lasers are ultra-fast pulsed lasers, often used for removing material. The difference between CW, micro and nanosecond lasers is that femtosecond lasers do not heat the material, but instead almost instantaneously create a plasma. This is because the pulses spread faster than the heat through the material.

With micro and nanosecond lasers the material is removed by melting and vaporising, which in turn leads to micro-cracks, melt zones and coarse surfaces. These undesirable side-effects don’t occur with femtosecond lasers, which makes them very interesting, especially to achieve surface functionalities via texturing.

In our first watch design we successfully designed an optical effect by creating a diffraction pattern inside a coating using our femtosecond laser. But now we’re looking for a special effect, so the search is on!

This article is part of our ‘4.0 made real by Sirris’ campaign, illustrating the feasibility of 4.0 technology in industry. Want to know more? Visit our landing page or LinkedIn page!