Powder-bed additive manufacturing of pure copper has been the subject of some research over the last few years. The most common laser used in AM machine has a wave length that is poorly absorbed by pure copper. This leads to excess reflection of the energy on the optical system and poor material quality.

One way to overcome this difficulty, is to change the wavelength of the laser to increase the abortion of the material. Another strategy is to use an electron beam that does not suffer from reflectivity issues like lasers do.

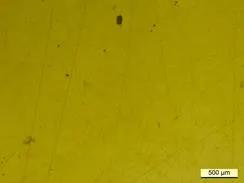

As a part of the PONAMP project, Sirris has developed pure copper printing on its Arcam A2 industrial 3D printer. The developments of an optimal parameter set were done by using the design-of-experiments method on cubes. The density was evaluated through Archimedes density and microstructural analysis. It was possible to achieve density levels above 99,5%:

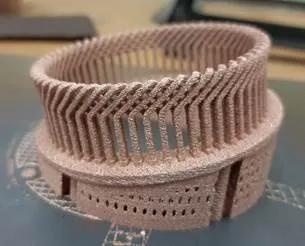

Figure 1: High density of the as-built stateSirris printed, as a demonstrator, the static winding of an electrical engine to illustrate the potential applications of the technology. Printing parts required the development of supporting strategies that take into account the specificities of copper as a material.

Figure 2: Pure copper winding for an electrical engineFurther developments shall include checking the density of the parts with respect to the optimisation procedure on cubes for consistency, next to electrical measurements of the as-built material.

Competences Sirris used in this project

- Validation and implementation of new materials

- Feasibility study and proof-of-concept

Could these competences be useful to your company or project ? Let’s find out and contact us!

You can read more on the PONAMP project in our previous blog post.

Source: 'A Review on Additive Manufacturing of Pure Copper', Coatings 2021, 11, 740. https://doi.org/10.3390/coatings11060740

PONAMP is a Cornet Project funded by national agencies members of the Cornet Network: German Federation of Industrial Research Associations (AiF) | Federal Ministry for Economic Affairs and Energy | Service Public de Wallonie - DGO6 (SPW).

Project partners: Materia Nova, UMons, Fem, Fraunhofer Umsicht