Within the Enable project we accomplished the latest development in treatment of data coming from SLM melt monitoring for quality control of additive manufacturing parts.

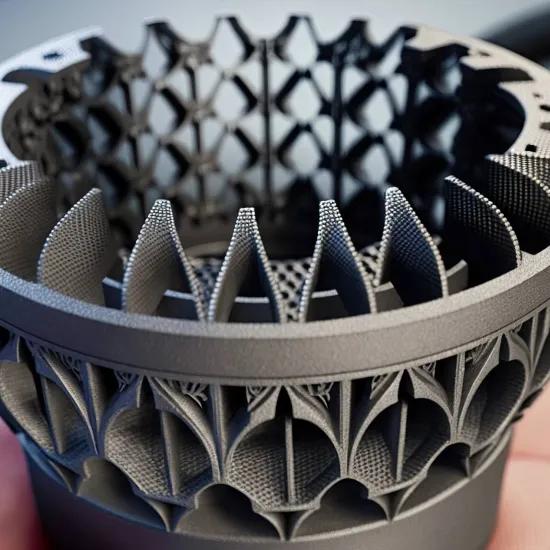

The additive-manufacturing technology SLM (Selective Laser Melting) represents a major technological breakthrough and allows us to produce geometries that are impossible to manufacture with conventional technologies such as machining or foundry. The development of parts with this technology, especially in the aeronautical industry, requires the control of the quality of the manufactured parts: this includes the surface condition, defects such as porosities and cracks, microstructure, presence of interstitial spaces, etc.

Within the Enable Project, Sirris is working on how to use in-situ monitoring systems to easily detect these defects with non-destructive controls. For this purpose, we used our machines equipped with melt pool monitoring system and camera to record the manufacturing conditions (see: Figure 1).