Versatile bio-based material ready for industrial application

In the pursuit of sustainable practices and the transition to a circular economy, businesses are increasingly exploring the potential of biobased materials. One of these materials that gets increasingly more attention is nanocellulose. As it is a versatile and environmentally friendly material with a wide range of potential applications, it is an attractive choice for industries seeking more sustainable materials and products.

What is Nanocellulose?

Nanocellulose is primarily composed of cellulose, which is a natural polymer found in the cell walls of plants. Cellulose is one of the most abundant organic compounds on Earth. This versatile and abundant material is derived from natural sources such as wood, fibre crops and recycled biomass, offering a sustainable alternative to traditional materials. The choice of source and the specific processing methods used can influence the properties of the resulting nanocellulose. The process of creating nanocellulose involves breaking down cellulose fibres into nanoscale components, which can be categorised into two main types:

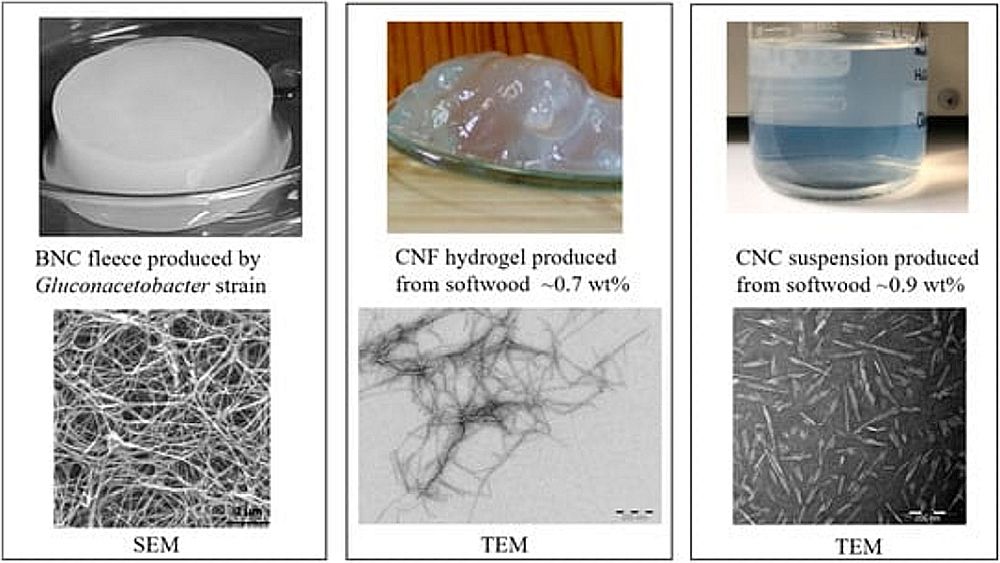

- Nanocrystalline Cellulose (NCC): NCC consists of tiny, crystalline regions of cellulose and is obtained through the acid hydrolysis or enzymatic treatment of cellulose fibres. These nanocrystals are very small, typically measuring only a few nanometers in width and several micrometers in length.

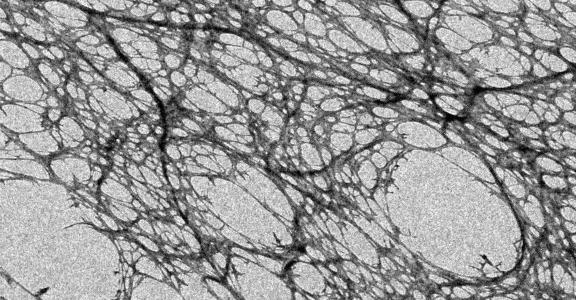

- Nanofibrillated Cellulose (NFC): NFC, also known as cellulose nanofibres or microfibrillated cellulose, is produced by mechanically disintegrating cellulose fibres into nanoscale fibrils. NFC can vary in size and aspect ratio, but is typically longer and less crystalline than NCC.

There also exists a third type of nanocellulose: bacterial nanocellulose (BNC), also known as microbial cellulose. This type of nanocellulose is produced by certain strains of bacteria. Unlike plant-derived cellulose, which is composed of microfibres or crystals, bacterial nanocellulose consists of ultrafine, nanoscale cellulose fibrils. This material is produced through the fermentation of bacterial cultures.

Why is it such an interesting material?

Nanocellulose has the advantage of being non-toxic, renewable and biodegradable, which makes it an attractive choice for industries seeking more sustainable materials and products. Each type of nanocellulose can create distinct properties in the new material.

NCC has a high strength and stiffness due to its high crystallinity. Its high aspect ratio makes it possible to reinforce materials and improve mechanical properties. It is optically transparent and has a good thermal stability.

NFC has a high surface area, which is beneficial for applications where adsorption, barrier properties or surface modification are important. NFC is more flexible and less rigid than NCC, making it suitable for applications where flexibility and conformability are required. It can absorb and retain water easily.

BNC is biocompatible and very pure compared to the other types of nanocellulose. It can be used in direct contact with biological tissues. It has an exceptional ability to retain water and has good mechanical properties, such as flexibility and strength.

Apart from the type of nanocellulose, specific properties can also vary depending on the source material and the processing methods used.

Market and Potential applications

All this makes it a versatile and environmentally friendly material with a wide range of potential applications:

Medical: for drug delivery systems, wound dressings, and tissue engineering scaffolds.

Packaging: to enhance the strength and barrier properties of paper and cardboard products, reducing the need for plastic-based packaging materials.

Aerospace, manufacturing and construction: to create lightweight and reinforced materials.

Textiles: to improve the strength and durability of textiles.

Food: to create edible coatings for food packaging.

Electronics: as transparent substrates for printed electronics.

The wide (forecasted) applicability of this material makes that the nanocellulose market is on the rise, with a projected growth from 346 million USD in 2021 to 963 million USD by 2026 and a compound annual growth rate (CAGR) of 22.7%. While precise pricing may vary, estimates suggest that nanocellulose products could range from 7 to 12 euros per kilogram of dried material, enhancing their competitiveness and accessibility.

Want to know more?

As we believe this material can become a game changer in future applications, we want to introduce you to this material during a seminar with experts in the field, from Belgium and abroad. Don't miss this opportunity to delve into the world of nanocellulose and explore how it can enhance your company's sustainability, innovation and competitiveness: check our agenda regularly or contact us, we'll be happy to keep you up to date!