Over the years, various calculation models have been developed that allow machining processes to be analysed and even optimised. These calculation models can be run on the online platform modelgebaseerdbewerken.be by means of simple forms. In a series of blog posts, we explain how you can use this platform in practice. In this third part, we look at how you can quickly check pre-set cutting conditions.

Once you have selected a milling tool for a particular operation, you will often be given suggestions for cutting parameters to get the best performance from the tool. These suggestions are usually given as a function of the diameter or for a specific combination of cutting width and depth. In many cases, these recommendations are based on extensive testing by the supplier and therefore very accurate within the set limits.

But what if you need to do something a bit different? What if your workpiece needs more tool overhang? What can you expect then? By what factor should you increase or decrease the recommended parameters?

Setting limits

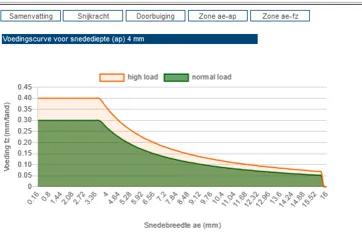

The 'Milling' model calculates both the load on the tool and the deflection this causes. By setting limits on the allowable load and deflection (in combination with the material characteristics of the tool) the model is able to show cutting zones.

Since the model is available to everyone, the limits are set conservatively. In concrete terms, this means that cutting parameters within the green zone should not pose a problem for the specified tool. Cutting parameters outside the coloured zone are certainly possible, but can lead to such things as a high - perhaps excessively high - milling load, a reduced service life for the tool and vibrations.

The purpose of the calculated cutting zones is to allow a quick decision: are the predetermined parameters within the comfort zone of the tool or are they outside, where some caution would be required?

Extra tip: be sure to vary the tool overhang to get an idea of how much the length-to-diameter ratio affects the cutting zones.

Modelgebaseerdbewerken.be

Access to the platform is free of charge, but you do need to register.

- Step 1. Register via the Sirris portal

URL: https://portal.sirris.be/modelgebaseerde-bewerken-login

Important: The code is generated immediately and displayed on the screen. So write it down or copy it immediately.

- Step 2. Go to the online platform

URL: http://www.modelgebaseerdbewerken.be/index.php

- Step 3. Go to the login screen (top right button)

- Step 4. Log in with your e-mail address and the generated code

You will also find the necessary explanations about working with the models on the platform, but be sure to keep an eye on the Sirris diary because we will be organising both physical and online explanation sessions.

The online platform is part of the COOCK project 'Model-based machining', which was launched with support from Flanders Innovation & Entrepreneurship (VLAIO).