Over the years, various calculation models have been developed that allow machining processes to be analysed and even optimised. These calculation models can be run on the online platform modelgebaseerdbewerken.be by means of simple forms. In a series of blog posts, we explain how you can use this platform in practice. In this first part we will discuss the 'sweet spot' in milling.

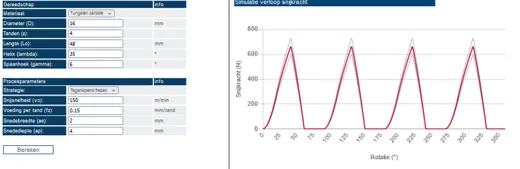

Unlike in turning, a milling operation has by its very nature an interrupted cut since a tooth or cutting plate will enter and exit the workpiece with every rotation. This puts the cutting edge under a fluctuating cyclic load with each rotation. This load is shown in the 'Milling' model by the cutting force curve. The example below shows that each of the four cutting edges of the milling tool experiences a fluctuating cyclic load. Moreover, with these cutting parameters there is always a moment when no edge is actually cutting, so you can say that the milling tool gets four ‘taps’ with every rotation. This combination of tools and cutting parameters therefore induces a vibration that rises from microscopic to clearly noticeable as the feed rate increases.

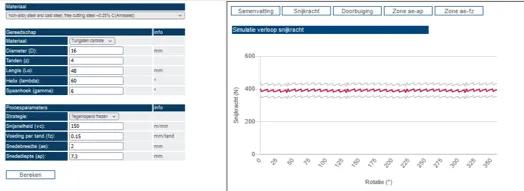

Constant cutting load

By opting for a different combination of tools and/or cutting parameters you can ensure that the decrease in load caused by one cutting edge exiting the cut is compensated by the next tooth entering it. The figure below shows the effect on the cutting force profile, and consequently on the stability of the milling tool. The milling tool now experiences a constant load, resulting in much less noise.

This type of situation is also known as the 'sweet spot'. The term is often used for an optimal depth of cut for a specific cutting tool. Milling at the sweet spot can prevent quality problems and other issues, especially in vibration-sensitive operations such as when using slender tools or making thin walls.

On the online platform, the sweet spot for the tool you intend to use is calculated within the ‘Milling’ model. You can also have the model calculate different milling geometries because the cutting depth is not the only factor: the number of cutting edges and angle of inclination also play a role.

Modelgebaseerdbewerken.be

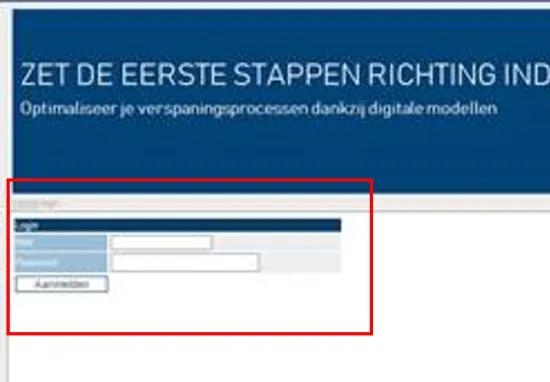

Access to the platform is free of charge, but you do need to register.

- Step 1. Register via the Sirris portal

URL: https://portal.sirris.be/modelgebaseerde-bewerken-login

Important: The code is generated immediately and displayed on the screen. So write it down or copy it immediately.

- Step 2. Go to the online platform

URL: http://www.modelgebaseerdbewerken.be/index.php

- Step 3. Go to the login screen (top right button)

- Step 4. Log in with your e-mail address and the generated code

You will also find the necessary explanations about working with the models on the platform, but be sure to keep an eye on the Sirris diary because we will be organising both physical and online explanation sessions.

The online platform is part of the COOCK project 'Model-based machining', which was launched with support from Flanders Innovation & Entrepreneurship (VLAIO).

|

|