LED lighting is currently breaking through in various branches of the lighting industry. This type of lighting is powerful, economical and has limited dimensions. For a more efficient production, femtosecond laser technology can be used.

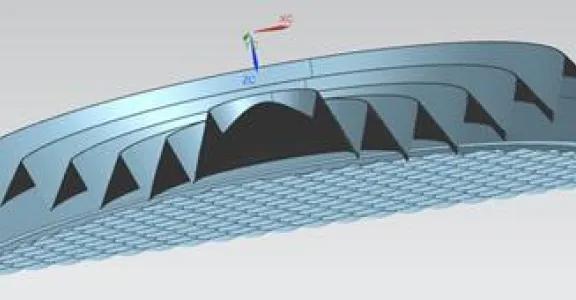

The picture above shows a cross section of a circular lens design. The angular upper part is the Fresnel part and the micro lenses are at the bottom.

LED light originates from a small surface area. This is referred to as a point source. It makes it possible to direct the light for optimal spreading. By using a Fresnel lens in combination with microlenses, the necessary lens material and the desired dispersion is obtained.

A lasered microlens array in a hardened mould material, measured by confocal microscopy (3D)The Fresnel section collimates the light. By using the hexagonal microlenses, the light is distributed in a controlled circular way with a divergence of 10 percent, which is not possible with a traditional diffuser. Furthermore, the many facets ensure a spread of intensity, so that you are not blinded when looking at the lamp. Finally, a better colour uniformity at the edge is obtained by colour mixing, so that the dispersion effect fades away.

The mould with microlenses is made using femtosecond laser technology. This new laser technology is known for the purity of the structures compared to a more traditional nanolaser (see picture above). The Fresnel section was milled.

In this case, KU Leuven takes care of the design of the lens and the measurement of the light performance. Sirris makes the mould and Dow Chemical takes care of the injection moulding. This is within the framework of the 'Lighting Industry 4.0: High-tech production means for lighting the future' project.