The Belgian lighting industry has not been spared from global developments in production process digitisation and innovation. As competition increases, companies need to stand out for their innovation, attractive designs and production processes that allow the manufacture of cost-effective, smaller and personalised lighting solutions. The required technology, such as 3D printing, laser texturing, high-precision machining and cobot-assisted assembly was once uncharted territory for many manufacturers. Groen Licht Vlaanderen, the VLAIO cluster that represents the lighting industry, approached Sirris with the following simple request: to ensure lighting industry companies are aware of these technologies and are supported when they start implementing them.

Redesigning the heat exchanger

One of the challenges suggested by the lighting industry was the heat exchanger. This thermal component is integrated in the product, hidden from sight. It has no aesthetic function but is essential to dissipate the heat produced by LED lamps. Sirris redesigned the heat exchanger, taking the following factors into consideration: minimum weight, minimum geometric volume and an attractive look, so it no longer needed to be hidden and would add value to the lamp. The reduced weight would also result in lower costs and make installation easier and cheaper.

Additive manufacturing and the geometric freedom this technology provides were applied to achieve the best possible results. We managed to halve the weight of the thermal element yet still increase performance by 15%, as well as an aesthetically pleasing design, an important factor in the value of a lamp.

Smart lamp

As part of incremental digitisation, the Internet of Things and the rise of Lighting as a Service – whereby customers purchase a quantity of lux rather than a physical lamp – a temperature sensor was added to the thermal element. The sensor enables you to control lamp performance and replace the LED bulb in time, e.g. when its temperature becomes too high.

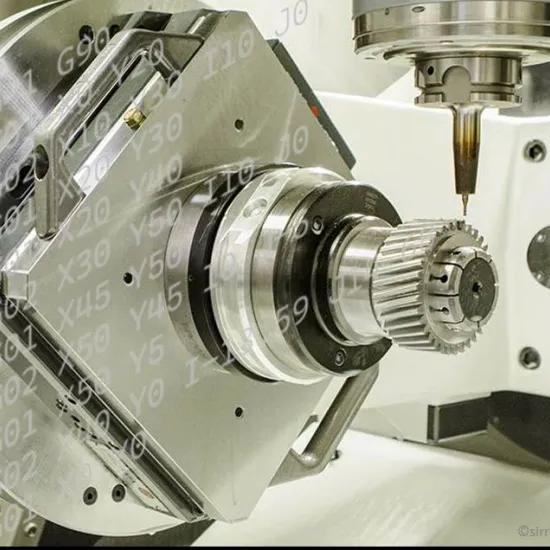

The sensor is manufactured via a combination of coating technology and ultrashort pulse lasers, which means the temperature can be measured very accurately and reliably on very small surfaces. Service providers can check their lamps remotely in real time, and if necessary, replace them if a defect occurs.

Sirris has managed to transfer their process knowledge, models and experience to the lighting industry for both these modifications, making it easier to work on advanced production technologies.