The friction behaviour of surfaces can be tuned by laser structuring. Recently, an industrial application of controlling friction by surface texture is presented for large marine ship engines. In the assembly of the driveshaft a safety mechanism is built in, to deal with excessive forces. The disc-based system is designed to start slipping at a certain threshold force.

The friction discs transfer power in ship engines and act as a safety device. They need to sustain a precise amount of friction: too much and the gear can be overloaded, too little and there could be premature slippage. Until now, to help them create friction the friction discs are treated with a thermal spray, resulting in a spread on the threshold force of about 13-14%. This method is not precise enough for industry.

New surface-texturing laser process

Therefore, scientists from Heriot-Watt University in Edinburgh, Scotland, have conducted research in cooperation with the German company Man Energy Solutions and Danish firm TRD Surfaces to develop a new process for the discs.

A practical two-step process, consisting of laser surface structuring and subsequent deposition of a hard chromium carbide layer, was developed for the manufacture of well-defined high-friction surfaces, with a focus on application in driveshafts of marine engines. Process development focused on providing improved reproducibility compared with the current solution of thermal spraying. A new laser surface-texturing process is used to provide a suitable surface topography, and results are presented for two different nanosecond-pulsed laser systems: 20 W and 200 W. It is possible to successfully create high-friction surfaces with either laser, but the 200 W laser significantly decreases the laser processing time, making it more industrially viable. A coefficient of static friction of 0.74 (0.6 requirement) and a relative standard deviation of 3–4%, as opposed to 13–14%, were achieved. The high-friction concept was combined with a surface hardening process, carried out by TRD Surfaces. It effectively freezes the textured surface to ensure it does not deform when it comes into contact with its counterpart.

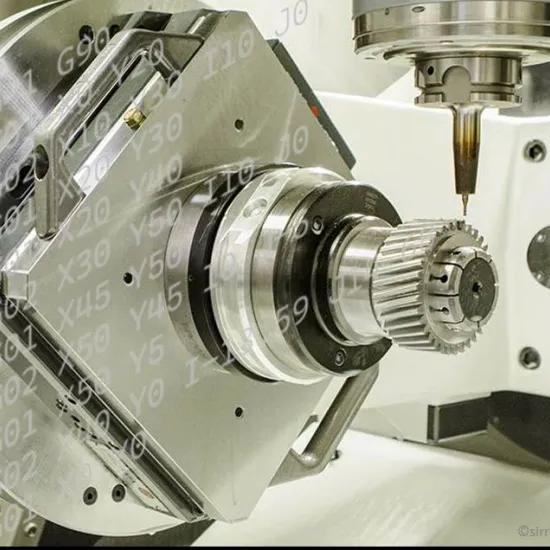

A topography map of the surface is shown in the figure below. Holes are made by individual nanosecond laser pulses at a pitch of 80 µm in a hexagonal pattern (left). After laser texturing a TRD CrC hardening process is carried out (right).

Surface texturing resulting in regular array of holes (left) that next is treated by a TRD CrC hardening (Source: Heriot-Watt University)

The laser-textured friction discs could reduce maintenance costs and downtime of large ship engines. Man Energy Solutions tested the friction discs on its two-stroke engines on two ships sailing from Europe to Asia.

At Sirris, research is conducted on this type of surface texturing by lasers. Surface properties can be altered: friction, hydrophobicity or radiation absorbing among others. Feasibility experiments on your materials and applications are available on our femto-second laser platform. Therefore, if you have any question laser texturing or functionalized surfaces contact us!

This blog is written as part of the COOCK project Surfacescript. Want to know more about the possibilities of laser texturing?