Equipment based on microfluidics is slowly finding its way into everyday life. Just think of the now well-known COVID-19-PCR test. The classic way to manufacture the moulds for these microfluidic systems is by machining (EDM). An alternative with additional advantages is the femto-laser.

Microfluidic technology can be applied anywhere where liquids, gases and dissolved substances are handled and scale is an issue. Specifically, this includes printing technology, the synthesis of chemical products, the detection of hazardous substances and biological and medical analyses of, for example, body fluids, DNA and even individual cells.

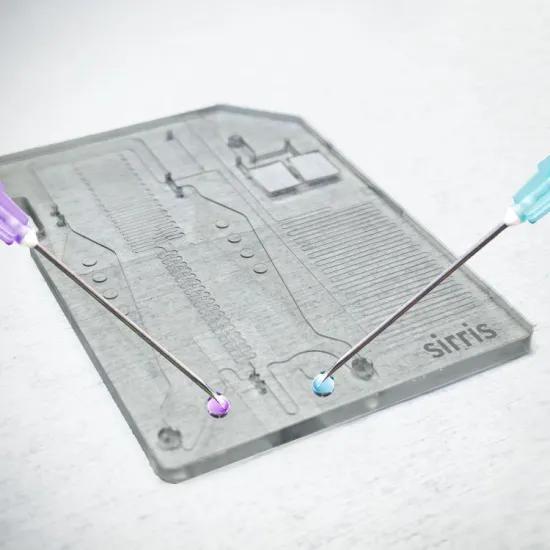

In microfluidic systems, small amounts of liquid move through microchannels for analysis. Larger numbers of these small labs are manufactured via injection moulding in a mould or die. Traditionally, such a mould can be made by machining (EDM). However, there is another way: the image below shows a mould of a microfluidic pump lasered with a femto laser. This type of laser works accurately and precisely, without melting the material. It is therefore a cost-effective and time-efficient alternative or complementary technique to more traditional machining or EDM.

The insert in the image above is for a microfluidic pump and manufactured at Sirris via femtosecond laser ablation. The channels are 300 µm wide and deep. Dimensions of the mould: 4 x 3cm

This blog is written as part of the SURFACESCRIPT COOCK project supported by VLAIO.