Goddeeris, a Roeselare industrial supplier, specialises in the machining of complex castings. During machining, it is essential to prevent vibrations caused by the equipment. The vibrations can be caused by a combination of tool geometry, machining and forces at specific frequencies. This ultimately leads to more downtime, faster tool wear and an unacceptable product finish. Vibrations are also one of the biggest challenges for companies working in heavy machining.

Goddeeris reached out to Sirris to find a vibration-free way to process large castings. A joint VLAIO (Flemish Agency for Innovation and Entrepreneurship) SME development project led by Goddeeris and Sirris was set up to collect information on the performance, phenomena and options to address vibrations during machining processes. This knowledge gives Goddeeris improved control on the production process in future.

Longer life cycle

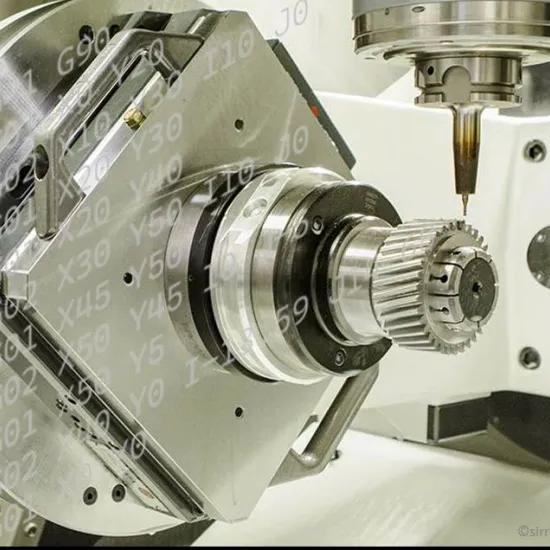

The effect of forces and process parameters resulted in rules of thumb and insight into the selection of the right settings to prevent vibration. A vibration-damping tool holder prototype was developed to study the effect of the damping of vibration and various parameters on the final results (such as quality and wear and tear of the tools).

Tests, sensor measurements and simulations were combined to research the vibrations, for which Sirris used the CutPro vibration simulation software. The number and size of the peaks were reduced (by a factor of 2 to 3), resulting in a lengthened life cycle for the tools and improved surface quality. This also reduced tool breakages and machine downtime.