Steel is a circular material because it is 100 per cent recyclable. In addition, it is collected, sorted and recycled on a large scale, and there is a market demand for these recyclates. Despite these fantastic references, there still seems to be a sustainability issue about steel. We’ll explain how fully circular is not necessarily fully sustainable and why circularity is more than recycling. We will dig deeper into this topic during our technical day on 9 March.

Impactless closed cycles do not exist, not even for steel

If we can recycle steel without loss of quality, will it be fully sustainable? We don't think so, and for good reasons:

When metal products or components are scrapped, not all metal parts go straight to metal recycling: metals may be contained in other fractions, metal structures may be cut into smaller pieces for transport, sometimes metals are already in an advanced state of corrosion, often consumables such as nails, screws, staples, blasting grids, welding electrodes, etc. are lost, some chips, turnings and grinding dust do not follow the most optimal route to recycling, etc. All these cases involve some form of loss of material and quality.

Losses due to collection will be very limited. The recycling process itself does cause some losses, mainly due to the quality of the scrap, due to e.g. coatings, the mix of steel grades due to non-separable joining techniques, the shape of the collected fractions such as uncompacted chips... All these elements affect the recycling efficiency.

The collection rate, sorting rate and recycling efficiency can therefore never prevent some sort of loss on the amount of steel in circulation. A need for new raw materials still remains, even if we close the cycle as perfectly as we can. In this sense, steel can never be 100 per cent circular.

Wat’s more important is the energy required to close these cycles. Each of these steps (collection, sorting, recycling) requires energy. Of course, the main focus is on re-melting in the recycling process. It seems unlikely that the energy needed can be covered by renewable sources in the short term. This means that the environmental impact of the recycling process is quite large.

To illustrate this, here are a few values expressed in eco-cost (€/kg). This simplified impact analysis shows the environmental impact in a single score (see also this earlier publication): for steel (market mixture with 21% secondary substances), the eco-cost is €0.48/kg, for steel pipes and profiles it is €0.5/kg. Of course, the credits for recycling are not 100 per cent the eco-cost of raw materials. They amount to less than half the eco-cost of raw materials, at -0.2 €/kg.

Therefore, we have to conclude that there are no lossless and impactless closed cycles, not even for steel.

Due to huge benefits, it remains important in circular economy

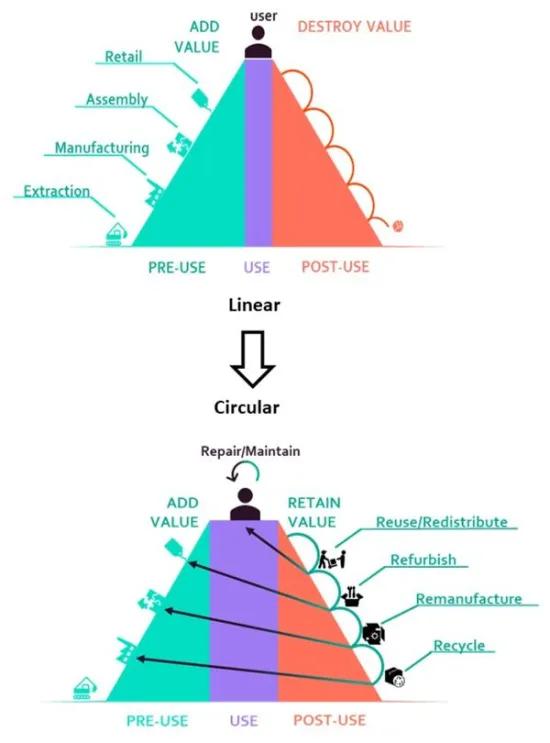

If we describe the circular economy as 'preserving the value of products, components and materials for as long as possible', the benefits of steel quickly become apparent.

In order to maintain the value of products, it is necessary to give them a long life. In such a context, steel is a great material and ideally suited for circular operations, requiring not only robust designs, but also services focused on repair, reuse, remanufacturing ...

It is in fact about using products and components for longer, but also making money from them. Without an adapted revenue model or additional services, a steel product designed for circularity is just an expensive version of that product. Conversely, expensive versions are often also more qualitative and thus have the potential of an extended lifespan.

Think gearboxes, steel structures for construction, bearings, steel used in transport (for rail, road and water), for which numerous types of services exist, including maintenance, upgrade, repair, refurbishing and remanufacturing. This type of services, which extends the life of products, also generates economic value. The bottom line is to use the added value of these services for circular design.

The impact of these services is that they ensure that we use the functionality of the products for longer. So, we can offer longer functionality with the same amount of material. For example, a gearbox can perform its function for longer and thus deliver value. Remanufacturing a gearbox has a much lower eco-impact (typically around 99 per cent less primary material and 85 per cent less energy required) than remanufacturing from raw materials. So the eco-impact for the total lifetime (first + second life) of such a gearbox is much lower than the eco-impact in case a second 'new' gearbox has to be manufactured.

This is why the circular economy is more than recycling. Recycling is useful and necessary, and we will continue to improve it, but the real lever to eco-impact reduction through the circular economy lies in life extension, especially for steel products.

A product is not in itself circular either. It is therefore necessary to handle products, components and materials differently, to change our behaviour. This is only possible if it benefits the user as well as the producer and the service provider. Finding those benefits and dividing the costs and benefits along the value chain, that is your circular challenge.

Find out more about this topic? On 9 March 2023, Sirris is organising a technical day on material testing, which will also cover circularity in the metalworking industry. More info about this event is available here.