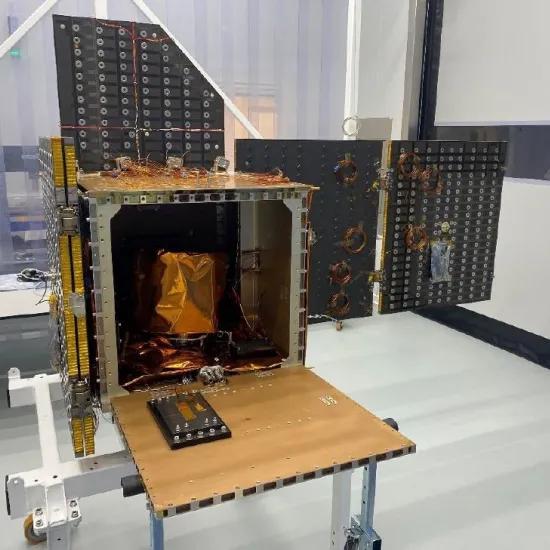

ESA and Sirris have regularly joined forces on previous AM projects. The current ambition at ESA is to broaden the introduction of the technology to their suppliers, by increasing current suppliers’ level of expertise in the technology, or by attracting new suppliers with AM knowledge that are not yet active in the aerospace industry.

Six projects with Belgian partners

In early 2019, eight projects were submitted to ESA, six of which were selected to be taken forward. A total of ten Belgian partners were involved in these six projects. The programmes started in July 2019, with stringent timescales and monthly updates required. Workshops are also organised regularly, to ensure the people working on the various projects can learn from each other. The aim of the projects is to set up real demonstrators in the short term, whereby the partners exchange as much knowledge on AM as possible. The projects have a one-year turnaround time and are expected to be completed by mid-2020. All the projects will be assessed on their business case: the further development of the demonstrators for the space industry. A country as small as Belgium will thus have taken a great leap forward in the future of AM in space travel.

Sirris was the second partner selected by ESA to set up an initiative in their own country. Sirris’s predecessor was Germany’s Fraunhofer Institute, which set up a similar initiative in one German region.

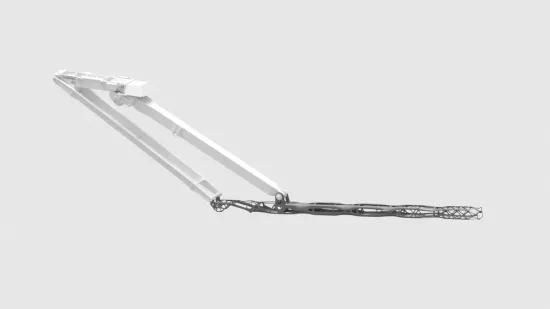

(image: Qinetiq)

In the scope of one of the projects, a new concept for an arm gripper was developed together with Qinetiq space and Raytech. The arm, which is more than 1 meter long, has been manufactured by combining additive manufacturing and laser welding. Sirris was responsible for the topology optimisation and the design of the arm.