When we use natural resources, we only pay the actors who extract these resources on the piece of land owned by that legal entity. We do not pay our planet for consuming these resources because no one 'owns' them, no one is liable for them. We have already provided a detailed description of these externalities in an earlier blog.

Now we would like to reverse the question: what would the price be if we wanted to avoid an environmental impact? Can we calculate the actual cost of a product if we wanted to avoid environmental damage? That is what the eco-cost method intends to do.

What is eco-cost and when does it make sense?

The eco-cost method calculates the avoidable eco-impact as a single number expressed in euros. In this sense, the method is very similar to those used in the Ecolizer (OVAM), where it is expressed in eco points.

The eco-cost method responds to our urge to tackle complex problems with a simple solution. It is very tempting to describe the full environmental impact of a product, including its use and end-of-life, in a single number. Everyone knows that this number will always be open to debate, while also lacking a lot of nuance.

However, there are some merits to this eco-cost method as well. It is a very suitable tool very early in the design process, when few data are available. After all, at that point, a lot of decisions still have to be made and you can still strongly influence the design. It allows you to quickly compare scenarios and make estimates on the environmental impact and how to reduce or avoid it. The euro values derived from the calculations are, however, only meaningful as relative values.

For example, if you want to compare two materials, it would be the right tool.

How does it work?

The eco-cost of a lot of materials, processes, transport, energy, end-of-life scenarios per material ... is available for a given unit. For example: Stainless steel 18NiCr8 has an eco-cost of 0.8 €/kg, transport by tractor-trailer (24 tonnes, min. weight/volume ratio 0.32 tonnes/m³) has an eco-cost of 0.031 €/(tonne.km).

Simple calculation rules (quantity x eco-cost) would therefore allow you to compare simple scenarios and calculate the eco-cost to be avoided. You can do this in simple or extensive spreadsheets, or you can use the apps on your smartphone. All the info to get started can be found here.

What is the real challenge?

The challenge is not, in fact, knowing that these tools exist and being able to use them. Companies that want to start using them are often looking for ways to integrate these calculations into their design process. Or they want to support their product designers to systematically incorporate circularity requirements into product designs. A common question is “Can you give me a 'circular design checklist' for my product that our designers can work with?” This is a very valuable question and ambition, only, there is not just one right checklist. Much depends on the design strategy ('Design for X'), which in turn is related to how you market the product and how you want the customer to interact with it. Do you want customers to opt for repair when their product is discarded? Do you offer the customer a buy-back option? Are you allowing customers to recycle your product through the established paths? You see, multiple options are available for the same product, which means that different design rules are required. So, the most appropriate sequence seems to be to determine the circular product strategy and from there map out the product requirements.

Case: electric hoist

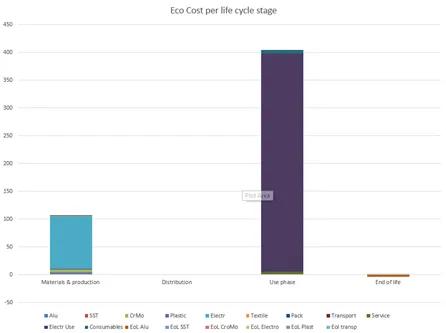

Based on the data on the main materials and their processing, logistics, product use, including maintenance, and product disposal, we obtain the following picture:

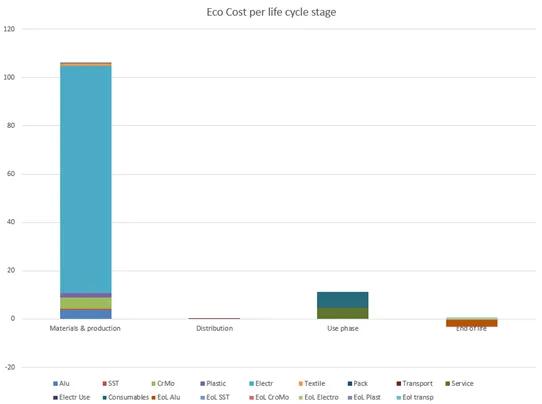

There is only a very small impact of the materials and their weight on energy consumption in this case. So, if we now remove electrical consumption from the equation, we get a better picture on the impact of materials.

In this case the impact of electronics emerges as dominant. For the company concerned, the circular design strategy aimed at parts recovery ('parts harvesting'), especially for the electronic modules, is a major asset. The economic drivers (availability and price) and the ecological drivers reinforce each other in this case.

In the subsequent stages of the design process, attention is paid to modularity and upgradeability ('upgradeability') of the electronic modules, among others. The framework conditions (standardised interfaces and tools, etc.) can also be examined to create a 'circular design checklist' on this basis.

Do you recognise these challenges and would like to address them in practice? Feel free to contact us! Together, we consider which pathway makes the most sense for you. That could include participation in our masterclass Integrate circularity in your product design (on 6 December), tailored individual coaching, a visit to a company that is already well on its way with this, or ...