As a leading manufacturer of wind turbine transformers, Mechelen-based CG Power Systems is continuously researching ways of making electrical machinery lighter and more compact without compromising on power. Before a new model comes to market, it is tested to ensure that it can withstand extreme climatic conditions. For this, CG Power Systems relies on the test facilities and expertise of the Sirris OWI Lab.

- Validation of prototypes under extreme climatic conditions

- Comparison of different versions by simultaneous testing

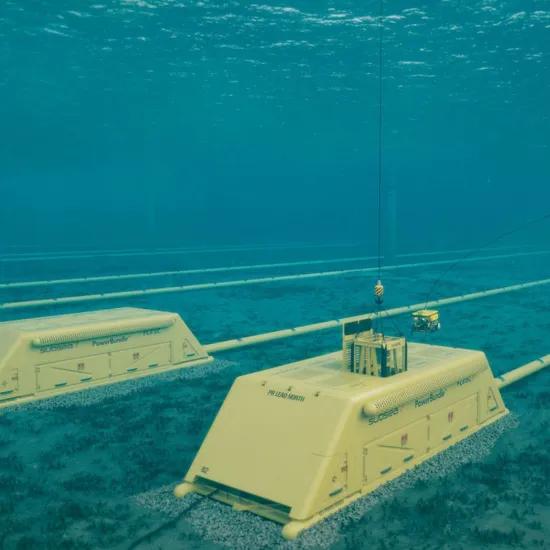

CG Power Systems is a global player in the wind industry. The Mechelen-based business makes transformers for onshore and offshore wind turbines and exports them to all corners of the globe.

“By testing prototypes of different versions in the climate chamber, CG Power Systems can bring new models to market more quickly, safe in the knowledge that they will perform in extreme conditions.”

Ever lighter and more compact

Ever more compact machinery with no loss of power or reliability: this is holy grail of the wind turbine industry, and transformer manufacturer CG Power Systems is no exception. A small, light transformer not only takes up less space in the turbine but also costs less to install. Of course, it is vital that the machine can still perform in all conceivable climatic conditions. Compact transformer models are therefore often fitted with liquid cooling systems and external heat exchangers or radiators. However, before being deployed in the field, the operational reliability of all these components has to be thoroughly tested under controlled conditions.

Machine and cooling system tested together

To this end, CG Power Systems regularly makes use of Sirris’s Offshore Wind Infrastructure Application Lab. The OWI Lab has one of the largest climatic test chambers in Europe and is used to carry out functional climatic test campaigns for cold, hot and tropical climates. The facility can accommodate and functionally test machinery weighing up to 150 tonnes.

Among other things, CG Power Systems tested a new cooling mechanism for its KDAF-type transformers. The cooling system and machine were tested together in the climate chamber, as if they were installed in an existing wind turbine. Six variants of the same prototype were also simultaneously tested in another test campaign. Simultaneous testing is not only much cheaper for the company but also means that different product versions can be compared under identical conditions.

Faster to market

The OWI Lab test campaigns validated both the KDAF transformer’s behaviour in desert heat and its cold start-up in extremely cold conditions. Based on the results, the KDAF transformer’s pump control system and fan were both further optimised. By testing different versions of prototypes under controlled conditions in the climate chamber, CG Power Systems can bring new models to market more quickly.