The answer is 'of couse, we can'! But 'why?' and 'what are the ways to do it?' are the actual questions that need to be answered.

It is true that the demands of the consumers are growing, leading to stringent requirements on manufacturing processes. Looking for a sustainable processes with reduced energy consumption and environmental impact, while increasing productivity, is the need of the hour for most manufacturing companies. Additive manufacturing methods have attractive benefits, such as fewer or no design contraints and lesser waste. Benefit of a CNC on the other hand is precision to a micron.

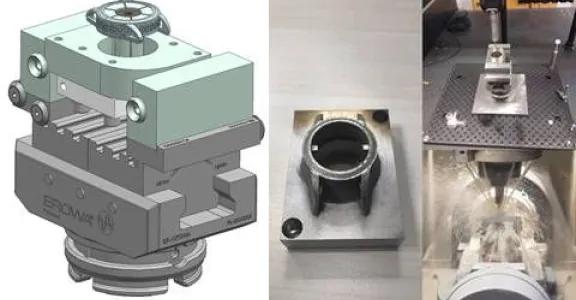

Best of both worlds

Imagine you can have a part with complex geometries, but still with high precision features. These two technologies can be complemented in such a way that the benefits of each manufacturing process can be fully realized. However, this is not as simple as it sounds. The two technologies have very different priciples and charecteristics. While an AM engineer cares more about the geometries and shape, the machinist would care for the final dimensions. However, the two of them work together. For example to ensure succesful machining, the part built with AM must have proper reference features. Questions such as 'how will the part be fastened?' and 'does the geometry permit tool access, amount of surplus material or overthickness etc.?' need to be answered already in the design phase, to ensure final part quality.

AM designers and CNC machinists work together to get this done. Sirris adapts this philosophy and does exactly this to get the two technologies to complement each other. The outcome is a part which can have a customised design with lesser material, but at the same time, it will not lack precison. We would continue to work to connect these two technologies in best possible ways.